Chemistry Reference

In-Depth Information

(USA). Morphology, surface texture and dimensions of the gold sputtered electrospun

nanofibers were determined using a LEO 1455VP (Germany) SEM. Fiber diameter

distribution and average fiber diameter were determined using Microstructure Mea-

surements software. Measurements of about 100 random points on the fibers were

used for determining fiber diameter distribution and the average fiber diameter.

RESULTS AND DISCUSSION

Electrospinning of Nylon 6,6 Solutions: Optimization of the Solution

Concentration

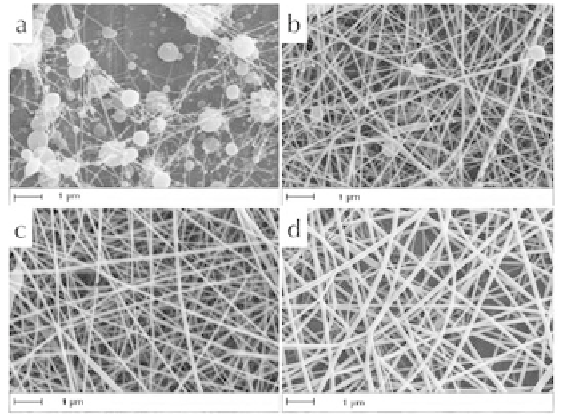

In order to optimize electrospinning solution concentration, nylon 6,6 solutions with

different concentration were electrospun in the applied voltage of 15 kV. SEM mi-

crographs of the electrospun samples are shown in Fig. 6.1. Attempt to obtain fibrous

structure from the nylon 6,6 solution with a concentration of 7% (w/v) was unsuc-

cessful; too many beads instead of nanofibers were formed. This could be attributed

to the low viscosity of the solution, which avoids the formation of a stable drop at

the tip of the needle. The concentration of the solution was then increased to 10%

(w/v). As the concentration increased, the total number of beads decreased. Increasing

concentration of the solution (12% w/v) led to lower number of beads and finally at

the concentration of 15% (w/v), no beads in the nanofibrous structure appeared and

the outcome was cylindrical, smooth, and continuous nanofibers. The average fiber

diameter for the fibers obtained using the 7%, 10%, 12%, and 15% (w/v) solutions are

58, 79, 83, and 128 nm, respectively. Viscosity is an important rheological property

to assess spinnability of the polymer solutions. Generally, there is a critical viscosity

for a solution to be electrospun; below this viscosity, chain entanglements would be

insufficient to stabilize the coulombic repulsion within the ejected jet, leading to the

formation of sprayed droplets.

Figure 6.1.

SEM micrographs of Nylon 6,6 nanofibers electrospun from different solution

concentration: (a) 7%, (b) 10%, (c) 12%, (d) 15%.

Search WWH ::

Custom Search