Geoscience Reference

In-Depth Information

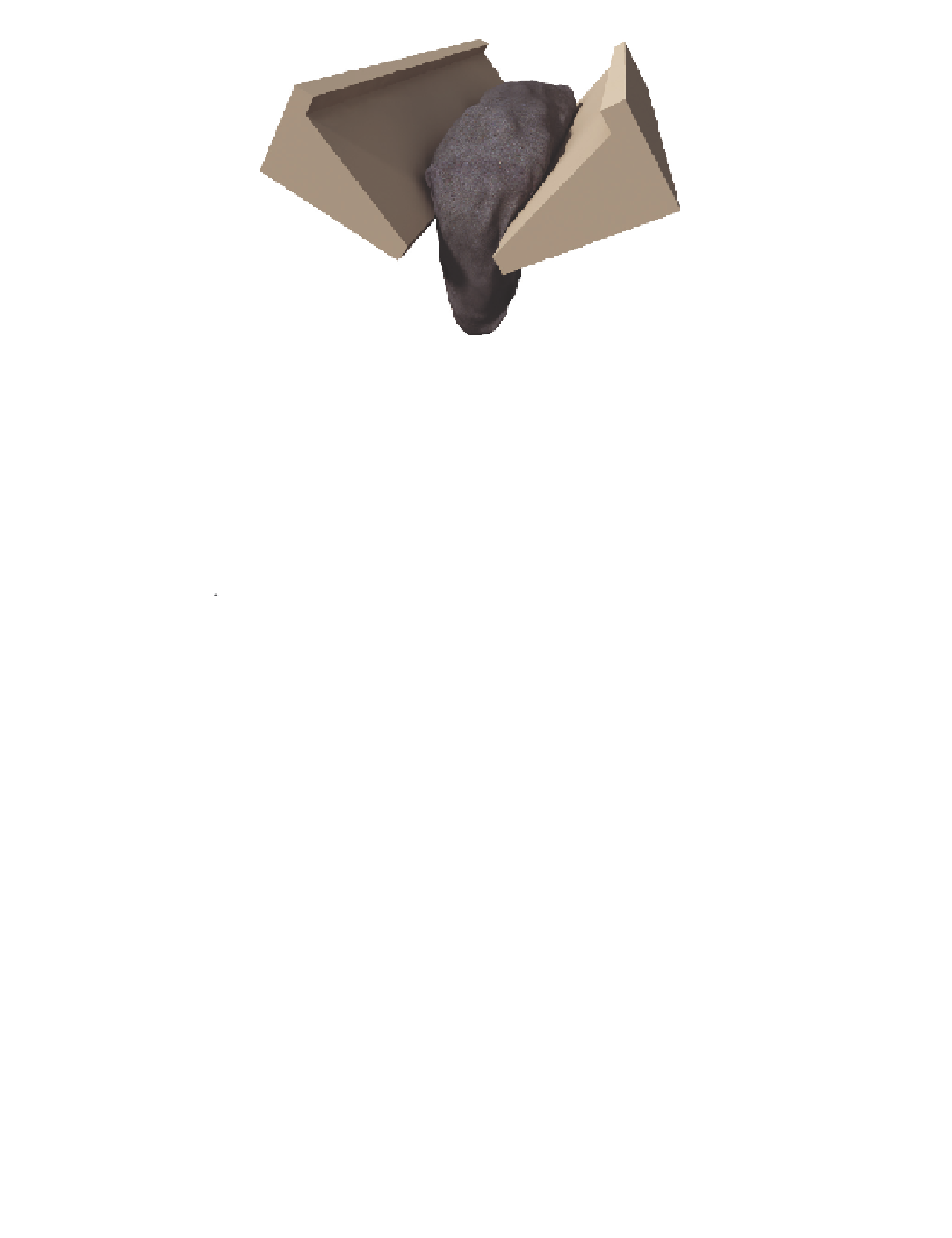

Figure 6.2

Sketch of a partially impeded geotextile container during the drop.

6.2.4 Degree of filling

The ultimate shape of a geotextile container depends mainly on the degree of filling;

theoretically 100% filling will result in a circular container. This manual, defines the

degree of filling of a geotextile container as the relationship between the actual surface

of cross-section of the container (perpendicular to the length) and its largest possible

surface of cross-section (a circle). The formula is as follows:

4

A

π

(6.1)

⋅⋅

f

=

S

where:

f

=

degree of filling [

−

];

A

=

filled cross-sectional area of the geotextile container [m

2

];

S

=

circumference of the geotextile container [m].

In Figure 6.3 the circumference is shown as a function of the degree of filling and

the cross-section. The grey shaded region shows the degree of filling between 20%

and 80%. This region is the most common for geotextile containers and tubes. From

20 to 50% are usual values for containers, from 50 to 80% for tubes.

The degree of filling of a geotextile container is defined in the literature in two

different ways. The common way (as shown above) is expressed as a function of the

circumference and the filled cross-sectional area of the geotextile container, but some-

times it may be defined as a function of the volume of the split barge. It should be

noted that these two definitions differ significantly. Thus, a degree of filling of 46%

can, according to the first definition, correspond to a degree of filling of 80% based

on the second definition. This difference is due to the shape of the split hopper bin in

cross-section. When in literature fill percentages of 70% and higher are stated, one

can assume that the degree of filling is calculated in relation to the volume of the split

barge and not according to formula 6.1.