Geoscience Reference

In-Depth Information

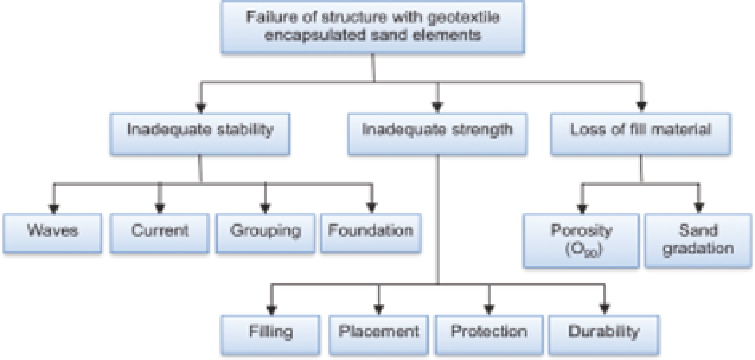

Figure 2.2

Fault tree for a structure with geotextile-encapsulated sand elements.

event occurring. Figure 2.2 contains an example of an appropriate fault tree for geo-

textile-encapsulated sand elements in a hydraulic structure.

2.4

MATERIAL ASPECTS OF GEOTEXTILES

2.4.1 Raw materials

When making a design using geotextile-encapsulated sand elements, the properties

and behaviour of the geotextile play a crucial role. This section provides an overview

of the key properties of the geotextiles used in Dutch geotechnical, road and hydraulic

engineering works. Much of this information has been taken from [12, in Dutch] and

[22], in which much knowledge related to the application of geotextiles in hydraulic

engineering is clustered.

“Geotextile” is the collective name for both woven and nonwoven materials.

Woven geotextiles are formed from yarns or tapes into an ordered 2-dimensional

structure. Nonwoven geotextiles comprise continuous or staple fibres that are ran-

domly oriented and form a stable structure due to mechanical (needle-punching),

thermal or chemical bonding. For geotextiles the following raw materials are used:

polyester (PET);

polypropylene (PP);

polyethylene (PE).

Table 2.2 lists some characteristic properties of the three raw materials used for

geotextiles.

In civil engineering PET, PP and, to a lesser extent, PE materials are used for

geotextiles. In environmental engineering it is mainly PE, and PET to a lesser extent,

due to the often prevailing chemical load.