Biomedical Engineering Reference

In-Depth Information

(c)

(a)

(b)

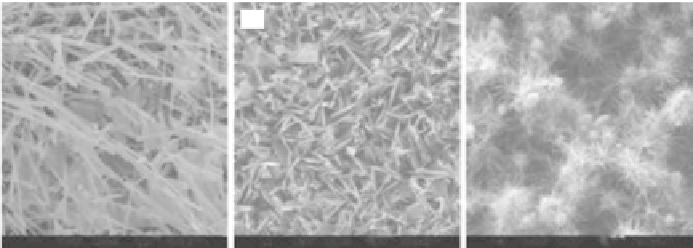

FIGURE 6.2

FESEM images of HAp powders with different morphologies: (a) rodlike, (b) platelike, (c)

chrysanthemum-like.

HAp microrods) could be obtained (Figure 6.2) (Liu et al. 2011). Recently,

we developed a novel process to synthesize element-substituted HAp with

controllable morphologies and chemical compositions using calcium silicate

as hard-template precursors in the absence of any surfactants and additives

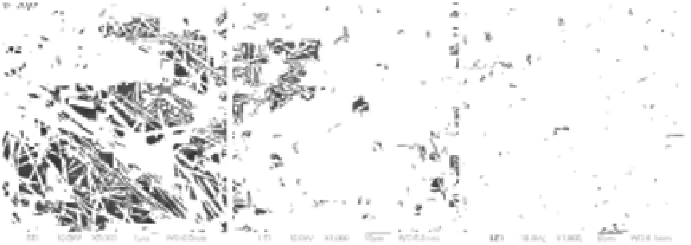

(Lin, Chang, Liu, et al. 2011). When hydrothermal treatment of the amor-

phous calcium silicate hydrate (CSH) precursor in Na

3

PO

4

solution occurs,

HAp nanoparticles with diameters about 90 nm were obtained (Figure 6.3a).

In contrast, when the crystalline calcium silicate (CS) powders were used as

the precursor and the Na

3

PO

4

solution was used as the phosphorus source,

the obtained HAp powders consisted of nanowires with lengths up to 2 µm

and diameters about 100 nm (Figure 6.3b). Figure 6.3c illuminates that the

obtained HAp powders via hydrothermal treatment with the crystalline CS

powders in NaH

2

PO

4

solutions had a smooth surface and ultralong sheetlike

shape with thickness about 100 nm, widths 1~5 µm, and lengths up to 20 µm.

The model of Ca

9

(PO

4

)

6

clusters (Posner clusters) with positive charge could be

(c)

(a)

(b)

FIGURE 6.3

FESEM images of HAp powders with different morphologies: (a) nanoparticles (CSH as pre-

cursor, Na

3

PO

4

as solution); (b) nanowires (CS as precursor, Na

3

PO

4

as solution), (c) nanosheets

(CS as precursor, NaH

2

PO

4

as solution).

Search WWH ::

Custom Search