Biomedical Engineering Reference

In-Depth Information

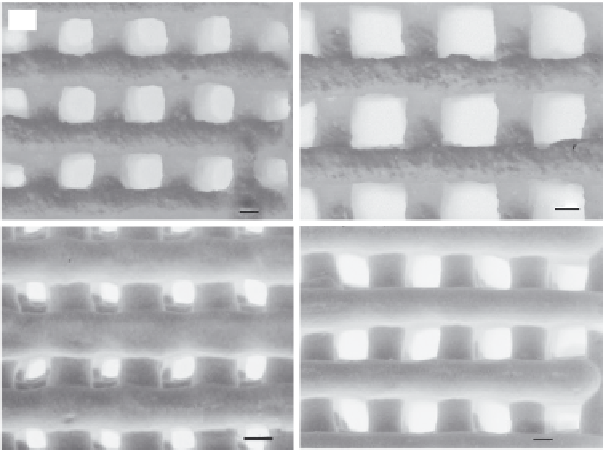

(a)

(b)

500 µm

500 µm

(c)

(d)

500 µm

500 µm

FIGURE 4.16

Light micrographs of plotted (a, b) β-CaSiO

3

and (c, d) mesoporous Ca-Si-P scaffolds with a

different pore size.

mesoporous Ca-Si-P scaffolds. For example, for mesoporous bioglass scaf-

folds prepared by polyurethane templating a compressive strength of only

0.08 MPa was reported (Wu et al. 2011), which is 200 times lower than that

of the plotted mesoporous Ca-Si-P scaffolds described herein. In addition,

compared to other polymer-ceramics composite scaffolds, the PVA-Ca-Si-P

composite scaffolds prepared in this work also have significantly stronger

compressive strength. For example, Kalita et al. (2003) fabricated polypropyl-

ene-TCP composite scaffolds by fused deposition modeling, leading to simi-

lar structures than those achieved by 3D plotting. The compressive strength

of the polypropylene-TCP composite scaffolds with a porosity of 36% was

12.7 MPa (±2 MPa), which is significantly lower than that of our PVA/Ca-Si-P

composite scaffolds, even though these had a much higher porosity of 60%.

We found that the compressive strength and modulus of the plotted meso-

porous Ca-Si-P scaffolds were clearly higher compared to that of the plotted

β-CaSiO

3

scaffolds. The potential reason for this observation relates on the

structure of the mesoporous Ca-Si-P particles with their regular nanochan-

nels and higher specific surface area: the Ca-Si-P particles can be bonded

stronger by PVA due to a partial filling of the nanochannels with the poly-

mer resulting in denser strands after extrusion.

The stress-strain curves of both bioceramic scaffold types indicate that

the stress increased linearly with increasing compressive strain until about

10% deformation (Figure 4.17a,b). After the maximum stress was achieved,

the compressive stress decreased with further increasing strain. However,

Search WWH ::

Custom Search