Geology Reference

In-Depth Information

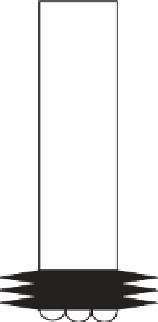

Drill collar

Displacement source drillbit model

x = 0, Rock-bit interaction,

Mechanical impedance model

Figure 4.2.3.

Downhole model near the bit.

4.2.4.4 Empirical notes on rock-bit interaction.

Penetration rate into a formation depends upon the entire drillstring

dynamics: the same bit drilling the same rock will penetrate differently with

different drillstring lengths. The dynamics is controlled by local interactions at

the bottom of the hole. This is clear to any home carpenter who has drilled with

new versus dull bits. In vibrations modeling, we view the simulation problem as

the result of two sub-problems. The first is

macroscopic;

this includes the

governing partial differential equation and the surface boundary condition. Its

description is determined by rig, drillpipe and bottomhole assembly details. The

second is a

microscopic

view related to events at the bottom x = 0. These

details, known as rock-bit interactions, are empirical: they depend on drillbit

geometry, bit and bearing wear, and formation hardness. What we seek is an

“absolute” statement about local interactions which can be used to show how

different drillstrings drill differently with bit and formation held constant. If this

statement is inferred from laboratory rig tests, the final result must be carefully

expressed in a manner relating bit and rock only. The effects of the drilling

assembly must be removed (or,

deconvolved

) so that the boundary condition can

be used with other drilling assemblies.

Laboratory drillbit data.

It is difficult to obtain true rock-bit boundary

conditions if the dynamics of the drilling assembly (i.e., the system transfer

function) cannot be characterized accurately. Controlled drilling where

vibration isolates the bit from reverberant oscillations is ideally desired. At least

in principle, information along these lines does appear in the drilling literature.

For example, Rowley, Howe and Deily (1960) performed laboratory drilling

Search WWH ::

Custom Search