Graphics Reference

In-Depth Information

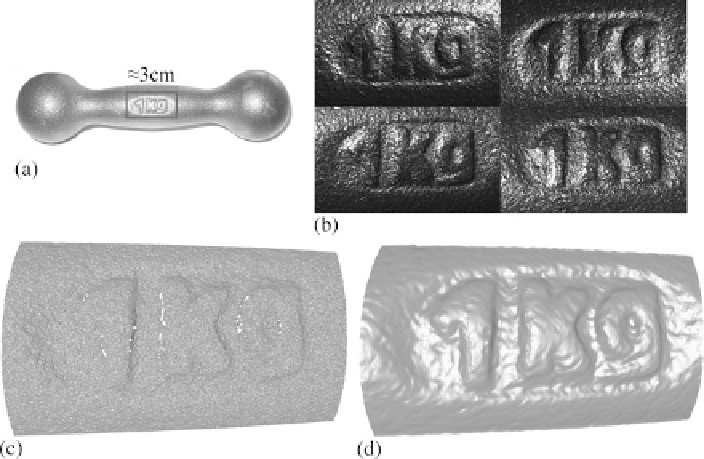

Fig. 6.32

Three-dimensional reconstruction results of an embossing on a dark, rough cast iron

surface. Image credit: S. Herbort. (

a

) Dumbbell-shaped object. The reconstructed surface part is

marked. (

b

) Four images from the set of twelve images acquired under different illumination con-

ditions. (

c

) Shaded view of the depth data determined based on projection of structured light. The

white areas

denote gaps in the data. (

d

) Shaded view of the three-dimensional reconstruction result

obtained with the combined method described in Sect.

5.5

The three-dimensional reconstruction result obtained with the combined method

has a high lateral resolution and reveals both the shape of the surface on large spa-

tial scales and most small-scale surface details visible in the acquired images (cf.

Fig.

6.32

d). The height of the embossing has been determined to 0

.

67

0

.

02 mm

by tactile measurement with a caliper gauge. The combined three-dimensional re-

construction method yields a consistent height value of 0

.

69 mm.

±

6.3.6 Discussion

It has been shown in Sect.

6.3.1

that the image-based approach suggested by Wöh-

ler and Hafezi (

2005

) can be used for three-dimensional surface reconstruction in

the context of industrial quality inspection. The shadow information provides depth

information on large spatial scales, while fine surface details are revealed by the

shading information.

The combined framework for three-dimensional surface reconstruction based on

photopolarimetric information and independently measured depth data proposed by

d'Angelo and Wöhler (

2008

) can be favourably used in the application scenario of

industrial quality inspection (cf. Sect.

6.3.3

). The accuracy of depth differences on

Search WWH ::

Custom Search