Graphics Reference

In-Depth Information

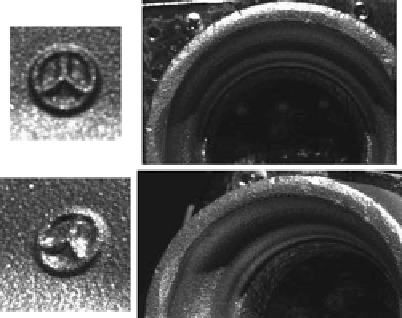

Fig. 6.23

Stereo image pairs

of the star pattern (

left

)and

the ring-shaped flange (

right

).

These examples illustrate

that, due to the specular

reflectance behaviour of the

surface, corresponding

surface parts do not

necessarily have a similar

appearance in the images

ences. Due to the small size of the surface defects, the accuracy of the tactile depth

measurement only amounts to 0

.

05 mm. The true depth of the dent 1 is 1

.

2 mm, the

reconstructed depth 1

.

3 mm. Dents 2 and 3 each have a true depth of 0

.

25 mm, while

the corresponding depth on the reconstructed surface profile amounts to 0

.

30 mm

and 0

.

26 mm, respectively. On large scales, our three-dimensional reconstruction

correctly displays a flat surface. These comparisons indicate a good correspondence

between the true surface and our reconstruction results.

6.3.4 Inspection Based on Specular Stereo

In this section the specular stereo method of Wöhler and d'Angelo (

2009

) described

in Sect.

5.4

is applied to the three-dimensional reconstruction of rough metallic

surfaces displaying a weak diffuse reflection component along with considerable

specular lobes and spikes. The same experimental setup as in Sect.

6.3.3.2

is used.

The surface of the connection rod, a cast iron surface displaying a star pattern, and

the ring-shaped surface part of the flange are examined. The first and third examples

have also been regarded in Sect.

6.3.3.2

. The presentation in this section is adopted

from Wöhler and d'Angelo (

2009

).

6.3.4.1 Qualitative Discussion of the Three-Dimensional Reconstruction

Results

Figure

5.20

displays a stereo image pair of the connection rod, while in Fig.

6.23

the stereo image pairs of the star pattern and the ring-shaped flange examples are

shown. The appearance of the surface of the star pattern differs so strongly between

Search WWH ::

Custom Search