Biomedical Engineering Reference

In-Depth Information

Table 1 Data demonstrating the effectiveness of a process analytical technology-based control

scheme in eliminating process variability. Adapted from Rathore et al. [

19

]

Run

Load purity (% )

PAT pooling

Pool purity (% )

Yield (% )

1

62.8

91.6

81.9

2

72.2

91.1

83.8

3

81.6

90.2

87.8

Identify TPP

Identify CQA

Risk Assessment

Define Product Design Space

Define Process Design Space

Risk Assessment

Refine Product Design Space

Process Characterization

Define Control Strategy

Risk Assessment

Filing

Process Validation

Process Monitoring

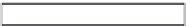

Fig. 15 Steps that need to be taken for implementation of QbD for pharmaceutical product

development. Adapted from Rathore and Winkle [

18

] and Rathore [

17

]

pooling of a process chromatography column, up to 20 % variability in the quality

of the incoming feed material results in less than 1 % variability in the product

quality of the resulting pool. If the same occurs at every step of the process,

variability can systematically be reduced or eliminated and the quality of the final

product will be very consistent.

Figure

15

illustrates the roadmap for QbD implementation and shows the key

steps that need to be taken for successful implementation of QbD for a pharma-

ceutical product [

17

,

18

]. Key steps are: identification of the product attributes that

are of significant importance to the product's safety and/or efficacy [target product

profile and critical quality attributes (CQA)]; design of the process to deliver these

attributes; a robust control strategy to ensure consistent process performance;

validation and filing of the process, demonstrating the effectiveness of the control

strategy; and finally ongoing monitoring to ensure robust process performance

over the lifecycle of the product. Furthermore, risk assessment and management,

raw material management, use of statistical approaches and process analytical

technology (PAT) provide a foundation for these activities.

Search WWH ::

Custom Search