Biomedical Engineering Reference

In-Depth Information

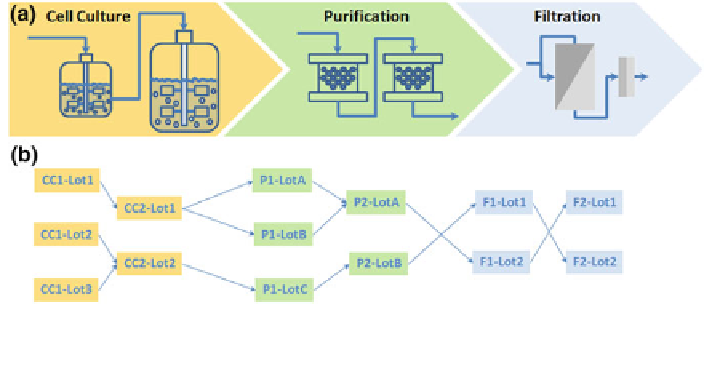

Fig. 4 a Example execution sequence of bioprocess unit operations. b Lot genealogy, involving

multiple splits and combinations

operation. Due to biological uncertainty and inherent process variability, the

upstream titres at the cell culture stage dictate the overall process sequence and

hence the need for flexible downstream processing. This flexibility usually results

in various splits, combinations and process step cycles, as shown in Fig.

4

b, and

poses a significant challenge in data management and root cause resolution.

1.4 Data Flow Map

Biomanufacturing involves leveraging a large amount of information for suc-

cessful process execution and continuous improvement. This information set

consists of not only process data from the current batch/run but also data from

historical batches and execution-related information, including:

• Data from process development runs and technology transfer reports.

• Previously executed commercial batches.

• Equipment usage and maintenance records.

• Clean-room environment data.

• Personnel training data.

• Current and historical process non-conformances and deviations.

Figure

5

shows various data, information and knowledge repositories and how

the content flows from one to another during normal execution of the commercial

manufacturing process lifecycle of a product batch. The information is maintained

in systems owned by various functional groups such as process development,

engineering, quality control, quality assurance and manufacturing.

As shown in Fig.

5

, process development engineers and scientists conduct

experiments to understand and develop a robust production process for manu-

facturing. The outcome of these experiments is development and technology

transfer reports. These reports form the basis of process validation activities for

Search WWH ::

Custom Search