Biomedical Engineering Reference

In-Depth Information

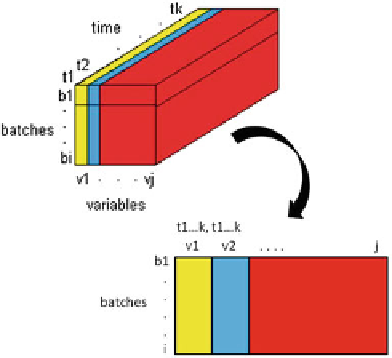

Fig. 2 Multiway

decomposition of a typical

3D bioprocess data array

consisting of time trajectories

of various variables for a

range of batches resulting in a

2D matrix with indicated

dimensions

3.2.2 PCA-Based Feature Extraction Case Study

In an unsupervised mode, PCA can reveal similarities between individual

bioprocessing batches, although a more frequent application is the detection of

deviation from 'nominal' or expected process behaviour. In this type of applica-

tion, historical examples of data representing 'nominal' or desired behaviour (e.g.

high concentration or quality/purity of desired product) are used together with

examples of process data deviating from this behaviour. Interrogation of score

plots may reveal the reason for the deviation between the batches, thus furthering

process understanding and enabling more effective process control and operation.

Figure

3

illustrates an example of a bivariate plot of the scores resulting from a

multivariate PCA analysis of historical process data collected during a typical

recombinant monoclonal antibody fragment production cultivation, with typical

online and offline measurements collected during the cultivations. In this particular

model 7 online variables, including pH, dissolved oxygen concentration and

temperature, and 13 design variables (whose values are changed during process

development) were used. Note that each batch is represented by a single symbol on

the plot. Given that the results, in terms of product concentration, are known at the

time of the analysis, it is possible to represent each high-producing batch in one

colour (in this case red) and low-producing batches in a different colour (green in this

case).

Figure

3

illustrates potential issues with the interpretation of the results.

A researcher may believe they achieved a very good clustering and be tempted to

draw arbitrary clusters A and B as indicated in Fig.

3

. However, when the same

figure is re-drawn with a different colour scheme, this time using black colour for

feed composition 1 (one of the design variables) and red for feed composition 2,

there is a much better separation, with one type of batch (high and low producing)

contained at the left-hand part of Fig.

4

while cultivations carried out with feed

composition 2 lie entirely at the right-hand side of the figure. Note that the

Search WWH ::

Custom Search