Agriculture Reference

In-Depth Information

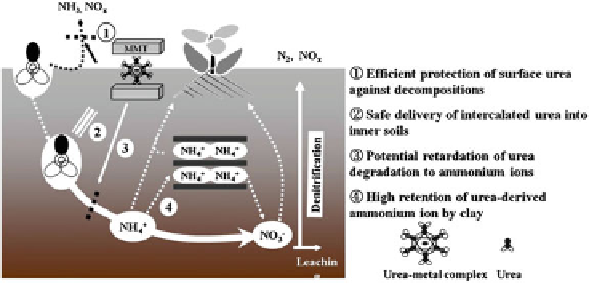

Fig. 11.3 An illustration for behaviors of intercalated urea molecules in soils. Reprinted (adapted)

with permission from Kim et al. (

2011

), copyright 2014 Springer

material from an agronomic point of view, i.e., the material (prepared by physical

mixing of the constituents and melting at 105

C) was not studied in terms of final

properties and their relations with the processing method. It is noteworthy that the

agronomic data are motivating and allow one to suppose that more attention in the

composite production stages could maximize the final results.

Pereira et al. (

2012

) demonstrated that nanocomposites produced from mont-

morillonite exfoliation into urea matrix can control the solubilization process of

urea, delaying its release to environment. The results showed that it is possible to

obtain a material processable by cold extrusion, with high N content and strength

compatible to the final application. Microstructural analysis of the nanocomposites

showed that the extrusion process generated two regions, one comprising the

nanocomposite itself (montmorillonite and urea) and the other with urea granules.

Thus, the authors attributed the release process not only to the clay mineral-urea

interaction but also to the creation of barriers to free urea diffusion out of the

granules. Scanning electron microscopy (SEM) images of these nanocomposites

and a scheme of the proposed pathway for urea intercalation during extrusion

process are depicted in Fig.

11.4

.

Hydrogels have been studied as polymer matrixes for controlled-release appli-

cation, specially because of their interesting properties in the release of water-

soluble inputs. Hydrogels are materials formed by long, flexible polymer chains,

which can be linked by covalent (chemical or cross-linked hydrogels) or physical

interaction (physical hydrogels) (Peppas et al.

2000

). Under specific conditions,

these materials can absorb large quantities of water as well as a nutrient solution

containing some active compound (Campese et al.

2007

). The difference between

chemical and physical hydrogels is in their chain formation: chemical hydrogels

cannot be dissolved once they are formed, whereas physical hydrogels can be

dissolved with external stimuli such as changes in temperature, pH, ionic strength,

etc. Due to these properties, hydrogels are used in a wide range of sectors, strength

in the manufacture of hygiene products (Singh et al.

2010

), agriculture (Leone

et al.

2008

; Sorbara et al.

2009

; Zhang et al.

2009

), drug delivery (Hamidi