Biomedical Engineering Reference

In-Depth Information

Calcium Alkoxide

Masuda et al. (1990) studied nanohydroxyapatite powder production using the alkoxide-based

system containing calcium diethoxide, triethyl phosphite, ethanediol, and ethanol, modified

with water and acetic acid. Within this system, they synthesized powders and found that the

determining factor for the composition of the resultant powder was the solution's pH. This

was the first systematic approach on controlling the chemistry for pure nanohydroxyapatite

production. No attempts were made to produce monolithic materials or coatings.

Based on the basic chemistry of Matsuda et al. (1990), Ben-Nissan et al. (Ben-Nissan and

Chai 1995; Chai et al. 1998; Gross et al. 1998; Ben-Nissan et al. 2001), and Green et al. (2001)

employed a modified alkoxide process to synthesize HAp powders and coatings via the

sol-gel technique. In a further modified technique, Milev et al. (Milev et al. 2002, 2003; Ben-

Nissan et al. 2001) used multinuclear NMR spectroscopy to monitor the synthesis of carbon-

ate-containing HAp for powder, nanoplatelets and nanocoating productions (Figure 2.9).

Layrolle and Lebugle (1994) developed a synthesis route of different calcium phosphates,

using anhydrous ethanol as solvent and calcium diethoxide (Ca(OEt)

2

) and orthophos-

phoric acid (H

3

PO

4

) as reagents. In a systematic approach using a simple variance of the

ratio of reagents, calcium phosphates of various chemical compositions Ca

x

(HPO

4

)

y

(PO

4

)

z

were precipitated in the ethanol. The solids that formed were characterized by different

physicochemical and thermal analyses. The results revealed that the different solid cal-

cium phosphates are amorphous and of the nanoscale and have large specific surface areas

and high reactivities.

Layrolle et al. (1998) also described the production of a nanosized, amorphous, and

carbonate-containing calcium phosphate powder synthesized from calcium diethoxide

and phosphoric acid in ethanol via a sol-gel method. They concluded that after sintering,

the decomposition of carbonated HAp generated a microporous ceramic with an average

pore size of 0.2 μm and an open porosity of 15.5% and that this microporous bioceramic

can be used as bone filler.

Roest et al. (Roest et al. 2001, 2004; Roest 2010) developed carbonate nanohydroxyapatite

coatings on anodized titanium and titanium alloy (Ti-6Al-4V) by dip and spin coating

methods successfully. Similar methods were used to coat a range of substrates with zirco-

nia nanocoatings.

Zreiqat et al. (2005) compared the effect of surface chemistry modification of titanium

alloy (Ti-6Al-4V) with zinc, magnesium, and alkoxide-derived hydroxy carbonate apatite

(a)

(b)

(Å)

1967

4

984

0

3

2

(µm)

3

1

2

(µm)

1

0

0

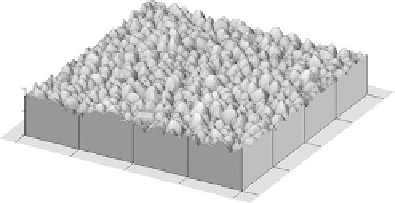

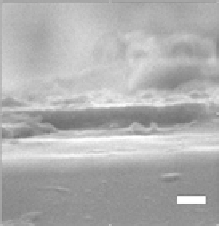

FIGURE 2.9

(a) SEM of nanohydroxyapatite coating (scale 100 nm), (b) AFM image of the same nanohydroxyapatite

coating.

Search WWH ::

Custom Search