Biomedical Engineering Reference

In-Depth Information

1. They can serve as a protective coating/barrier for corrosion and surface

degradation

2. They can protect host tissues from implant corrosion products

3. Bioactive glasses can significantly improve surface bioactivity, resulting in im-

proved tissue in-growth and attachment

Hydroxyapatite is the prevailing bioceramic coating material on metallic substrates.

There is an extensive literature database describing the development of hydroxyapatite

coatings on titanium implants to improve in vivo implant fixation of artificial teeth and

total hip joint prosthesis. There are some reports of CP (β-TCP, CaHPO

4

) coatings, Y-TZP,

and TiO

2

coatings on metallic substrates. In this chapter, I will only describe the applica-

tion of bioactive glasses as coatings on various substrates.

Regardless of coating material, the literature describes the following shortcomings asso-

ciated with coatings on metallic implants:

1. Limited adhesion strength of coatings with titanium substrates because of long-

term use in the body.

2. Composition of coated layers needs to be adjusted during the application pro-

cess. As a result, applied coating compositions often deviate from their desired

properties.

3. Limited selection of bioactivity of glass coatings due to compositional limitations

of the types of glasses that can be coated into metallic substrates while trying to

minimize TEC mismatch.

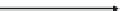

In order to improve the adherence of coatings on metallic substrates, various coating depo-

sition approaches have been explored (Figure 9.10). Starting with bioactive glasses in either

gas, solid, or liquid forms, bioactive glass coatings can be applied directly from the gas

or liquid state or be further transformed into either liquid (melt or slurry) forms before

deposition onto a metallic substrate. Coating methods include: chemical vapor deposi-

tion (CVD), physical vapor deposition (PVD), plasma spraying, electrophoretic deposition

Starting

materials

Transition

state

a

b

Gas

Gas

Coating

Liquid

(melt)

c

d

Solid

Substrate

Liquid

(slurry)

e

f

Liquid

FIGURE 9.10

Various routes (a to f) of coating formation on metallic substrates [26]. Routes: (a) CVD method, (b) PVD method,

(c) plasma-spraying method, glazing, and raid immersion, (d) EPD method, (e) sheet formation method and

slurry dipping method, and (f) electrodeposition method and sol-gel dipping method.

Search WWH ::

Custom Search