Biomedical Engineering Reference

In-Depth Information

Improvement in Wear and Corrosion Resistance

Metallic biomaterials are mainly applied to the load-bearing parts in the human body.

Wear debris generated from biomaterials by a tribological reaction are thought to be an

important factor related to implant loosening and bone resorption.

(89)

The surface of metal-

lic biomaterials are usually covered with spontaneously formed thin oxides (i.e., passive

films, which cause high corrosion resistance in metallic biomaterials). In the case that the

protective passive films on metallic biomaterials are destroyed by the tribological reaction

of wear debris, elusion of metal ions from the metallic biomaterials would be accelerated.

Therefore, the wear and corrosion properties of metallic biomaterials are closely related to

their biocompatibility.

Improving wear and corrosion resistance of metallic biomaterials by surface coating

using PVD methods has been conducted. TiN

(90-92)

and diamondlike carbon (DLC)

(93)

coatings have been prepared on metallic biomaterials using sputtering and ion plating

methods because of their high hardness and low friction coefficients. TiN coating on type

316L stainless steel and Ti alloys such as Ti-6Al-4V and Ti-6Al-7Nb showed improve-

ments in their tribological properties against ultrahigh molecular weight polyethylene

(UHMWPE

(90)

and corrosion resistance.

(90,92)

TiO

2

coating by PVD methods is another approach to improving corrosion resistance of

stainless steels and Ti and its alloys. An ion beam sputtering technique has been used to

deposit thick and dense TiO

2

coating on Ti and type 316L stainless steel surface.

(94)

The TiO

2

coating with the low defect concentration and a slow mass transport process across the

coating will improve the corrosion resistance and are also expected to improve the blood

compatibility of the implants such as artificial heart valves and stents.

(95,96)

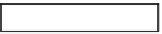

Factors Considered in Biomedical Coating on Metallic Biomaterials

Many factors should be considered when applying bioceramic coating on metallic bioma-

terials (Figure 7.36).

(97)

Tissue compatibility is the first priority of the bioceramic coatings

and is affected by surface morphology, phase, composition, and orientation of the coatings.

The high bonding strength between a coating and metallic biomaterial, which is affected

by physical and chemical properties and surface morphology of substrates, is also crucial.

Tissue compatibility

Phase

ɾ

composition

ɾ

orientation

Surface morphology

Mechanical properties

ickness

Coating

Substrate

Physical

ɾ

chemical

properties of substrate

Morphology

at interface

Bonding strength

FIGURE 7.36

Factors in biomedical coating on metallic biomaterials by vapor deposition.

Search WWH ::

Custom Search