Biomedical Engineering Reference

In-Depth Information

100

: Mirror-polished

: Blasted

80

60

40

20

0

ACP

OAp

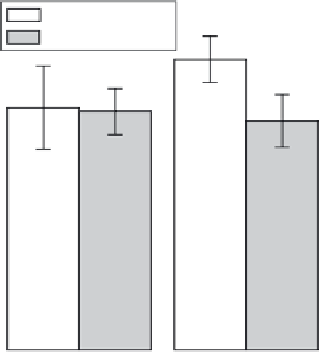

FIGURE 7.27

Bonding strengths of the ACP and OAp coatings fabricated on mirror-polished CP Ti and blasted Ti-6Al-4V

alloy substrates.

by plasma spraying, and (2) the removal of adsorbed gases on the substrate surface in RF

magnetron sputtering and the formation of a functionally graded layer in IBD. Table 7.3

suggests that the bonding strength is affected by heat treatment and immersion in aque-

ous solution such as SBF. The thermal expansion coefficient difference between a calcium

phosphate coating and a Ti substrate together with preferential and partial dissolution

of the coating would decrease the bonding strength. The bonding strength of coatings,

around 60 MPa, is close to that of the epoxy glue used in the pulling tests. As shown in

Figure 7.28,

(65)

the calcium phosphate coating prepared on a Ti substrate by RF magnetron

sputtering remained even after the pulling tests.

(33)

The actual bonding strength of the

coating would be more than 60 MPa. The bonding strength of the thin films to metal sub-

strates should be more precisely evaluated theoretically and experimentally.

The bonding strengths between α-TCP and HAp coatings prepared by thermal CVD and

Ti substrates are 48 and 42 MPa, respectively. These values are slightly smaller than those

of calcium phosphate coatings prepared by sputtering and IBD, but they are higher than

those reported in the coatings prepared by sol-gel and plasma spraying.

Apatite Formation in SBF

Apatite formation on a bioactive glass surface in SBF can be an indicator of

in vivo

bone

formation.

(66,67)

The apatite formation in SBF would be affected by the physical/chemical

properties and roughness of the substrate surface.

CVD can be used to prepare bioceramic coatings such as calcium phosphate and calcium

titanate with a wide variety of surface morphology and crystallographic orientation, and

apatite formation on these coatings in SBF has been reported. Table 7.4 shows the time

required for apatite formation in Hanks' solution over the whole surface of Ca-Ti-O and

Ca-P-O coatings prepared by CVD

(27,28,68)

and other coating methods

(69,70)

on Ti substrates.

Figure 7.29a and b show the surface morphology of the HAp coatings prepared by ther-

mal CVD after immersion in Hanks' solution for 3.6 and 21.6 ks, respectively. Apatite was

identified on the HAp coating after 3.6 ks, and the whole surface of the HAp coating was

Search WWH ::

Custom Search