Biomedical Engineering Reference

In-Depth Information

orientation to the

c

-axis of HAp increased with increasing RF power during the sputtering.

Since the biological apatite crystallites were reported to exhibit preferential orientation of

the

c

-axis (〈002〉 direction),

(42)

control of the orientation in calcium phosphate coatings on

metallic biomaterials will be effective for implant applications.

Ion Beam Deposition

IBD has been widely used for surface modification by combining ion impregnation and vari-

ous PVD techniques. IBD also includes dynamic mixing (DM), ion beam enhanced deposition

(IBED), and ion beam assisted deposition (IBAD). Ions are able to impregnate the surface of

solids by kinetic acceleration and the modified surface layer very strongly. Calcium phosphate

coating on a Ti substrate has been conducted by IBD by combinations such as electron beam

(EB) deposition/Ar

+

ion impregnation,

(12)

EB deposition/Ca

2+

ion impregnation,

(16)

and sputter-

ing/Ar

+

ion impregnation.

(17)

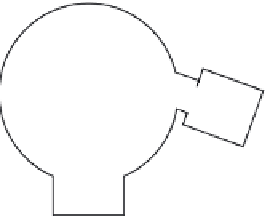

Figure 7.14 shows the apparatus of IBD for the preparation of HAp

coating on a Ti substrate.

(47)

During implantation of the Ca

2+

ions into the Ti substrate, an HAp

source material is evaporated using the EB gun and deposited in the Ti substrate in an atmo-

sphere containing water vapor. Figure 7.15 shows a schematic illustration of a graded coating

prepared by the IBD method. The graded coating can be prepared by controlling the amount

of the current of Ca

2+

ions and the amount of HAp evaporation. Ca

2+

ions are implanted into

the Ti substrate, and a mixing layer containing Ca

2+

ions and HAp is formed on the substrate.

The top surface of the coating is the HAp layer. Since the composition of the coating gradually

changes from Ti to Ti-Ca and Ca-P-O, the graded coating shows significantly strong adher-

ence to the Ti substrate. As-deposited coatings by these methods are usually amorphous and

then crystallize to HAp and β-TCP coatings by heat treatment.

(12,16)

Pulsed Laser Deposition

PLD is a common technique to prepare thin films by high-power pulsed laser ablation of

a solid target and subsequent deposition of the ablated species on a substrate. Therefore,

this method is often called laser ablation. A target can be instantly melted and directly

evaporated or be formed into atom/molecular clusters, and therefore the composition of

such thin films is usually very close to that of the target. Even complicated multicompo-

nent thin films can be prepared by PLD. A laser is emitted from outside the PLD chamber

and forms a plasma plume around the deposition zone without sensitive control of the

deposition conditions such as total pressure and gas species. Therefore, PLD has a wide

Vacuum

chamber

Substrate

Gas inlet

(H

2

O)

Ca

+

ion

source

Source material

(HAp)

EB gun

Exhaust

FIGURE 7.14

Schematic illustration of IBD apparatus.

Search WWH ::

Custom Search