Biomedical Engineering Reference

In-Depth Information

Magnetic field lines

Electric field

Electron

trajectory

E

Sputtered

area

B

S

Target

N

Permanent

magnet

FIGURE 7.8

Schematic illustration of magnetron and target.

RF magnetron sputtering is promising for bioceramic coating of metallic biomaterials

because highly adhered Ca-P-O coatings can be prepared uniformly at low temperature.

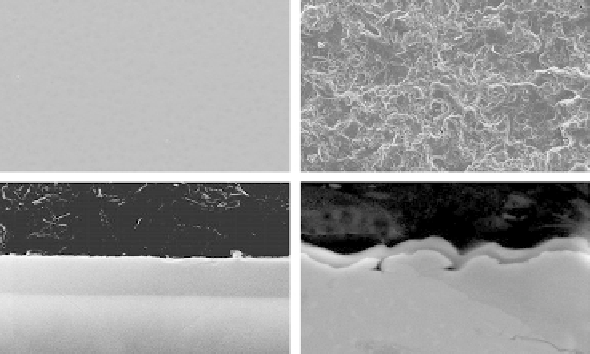

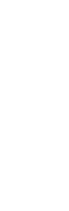

Figure 7.9 shows the appearance of amorphous calcium phosphate (ACP) coatings on mirror-

polished commercially pure (CP) Ti and blasted Ti-6Al-4V alloy substrates prepared by

RF magnetron sputtering. The surface feature of the coating well preserved the original

roughness of the blasted Ti-6Al-4V alloy substrate, proving good step-coverage even on

a complicated rough surface. Thermal spraying would not usually maintain the surface

roughness of the original substrate after application of a thick calcium phosphate coating,

while RF magnetron sputtering can achieve thin coatings with good adherence and cover-

age. Some studies on calcium phosphate coating on metallic biomaterials prepared by RF

magnetron sputtering have been reported.

(13-15,31-38)

The crystallinity of calcium phosphate

coating prepared by RF magnetron sputtering changed depending on process parameters

such as RF power, gas pressure in the sputtering chamber, and oxygen gas concentration.

Figure 7.10 depicts the effects of RF power and total gas pressure in the chamber on the

phase of calcium phosphate coating prepared at room temperature without the addition of

On mirror-polished CP Ti

On blasted Ti-6Al-4V

Surface

20 µm

50 µm

Resin

Coating

Resin

Cross

section

Coating

Ti-6Al-4V

CP Ti

1 µm

5 µm

FIGURE 7.9

SEM images of surface and cross section of ACP coatings prepared by RF magnetron sputtering.

Search WWH ::

Custom Search