Biomedical Engineering Reference

In-Depth Information

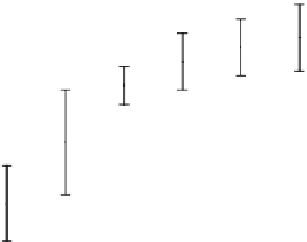

(a)

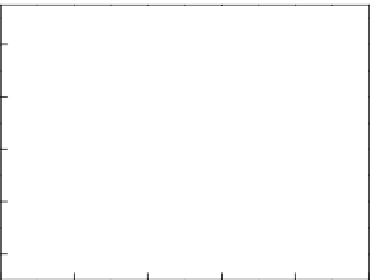

(b)

27

27

26

26

25

25

24

24

23

R

2

= 0.99

23

50 µm

20

400

500

600

700

800

0

20

40

60

80

100

Temperature,

T

(°C)

Index of crystallinity, IOC (%)

FIGURE 6.24

(a) Variation of Young's modulus as a function of heating temperatures. (b) A linear correlation between Young's

modulus and crystallinity (IOC) of HACs. Images show microstructural features of Young's modulus test pieces

with various IOC. (From Yang et al.,

Mater. Sci. Eng.C

, 26, 1395-1400, 2006. With permission.)

HACs herein. According to the Griffith-Orowan-Irwin theory, the fracture toughness of

a ceramic is correlated with the ability of impeding crack propagation (

γ

) and Young's

modulus (

E

) from the relationship:

K

IC

= 2

γ

[214]. The relative investigations indicated

that the improvement of fracture toughness can be approached to about 5% to 20% with

the increase in Young's modulus for the crystallization of HACs with performing heat

treatments [99,113,215]. In addition, the crystallization can also help to enhance the cohe-

E

, the crystallization can also help to enhance the cohe-

sion between splats boundaries within the coatings [211,212,215]. Therefore, the enhanced

bonding strength of the heat-treated HACs can be pinpointed from the improvement of

Young's modulus and fracture toughness resulting from the crystallization effect of HA

coatings. Although the bonding strength is improved with the crystallization of HACs

during vacuum and atmospheric heat treatments, note that detrimental effects accompa-

[99,113,215]. In addition, the crystallization can also help to enhance the cohe-

99,113,215]. In addition, the crystallization can also help to enhance the cohe-

,113,215]. In addition, the crystallization can also help to enhance the cohe-

113,215]. In addition, the crystallization can also help to enhance the cohe-

,215]. In addition, the crystallization can also help to enhance the cohe-

215]. In addition, the crystallization can also help to enhance the cohe-

]. In addition, the crystallization can also help to enhance the cohe-

. In addition, the crystallization can also help to enhance the cohe-

accompa-

nied with HA crystallization may result in the deterioration of bonding strength, as shown

in Figure 6.23. These deterioration effects are the crystallization-induced contraction, CTE

mismatch, interfacial oxide layers, and residual compressive stresses. Referring to the dila-

vacuum and atmospheric heat treatments, note that detrimental effects accompa-

heat treatments, note that detrimental effects accompa-

note that detrimental effects accompa-

that detrimental effects accompa-

s accompa-

the dila-

tation data of thermal dilatometry at 600°C to 800°C (from Figure 6.11 and Table 6.1), the

enlarged cracks, as shown in Figure 6.12, induced from the crystallized-induced contraction

(from 0.28% to 0.65%) of heat-treated HACs result in the deterioration of microstructural

integrity as well as the bonding strength. In addition, the crystallization-induced coating

contraction during high-temperature heat treatments will also significantly change the

coating/substrate interfacial residual stress states.

The residual stress of plasma-sprayed HA coatings can be measured using various meth-

ods such as the

σ

=

Eε

and sin

2

Ψ methods from XRD, Raman, analytical model, and the

specimen curvature method [197,202,210,216-219]. As described in the previous sections, the

substrate-removed HA coating layers not only can be used for the measurements of ther-

mal dilatations and Young's modulus, but also can be applied for measuring residual stress

states through the specimen curvature method [210,220]. For measuring the residual stress,

a 180 ± 20 μm thick HA coating is deposited on the substrate. After performing heat treat-

ments, the gauge length (

l

) of these heat-treated HA coatings, which are separated from the

substrates following the procedure detail described in [220], are measured. The curvatures

of the substrate-removed HA coating strips are determined from side-view photographs.

, and residual compressive stresses. Referring to the dila-

and residual compressive stresses. Referring to the dila-

Search WWH ::

Custom Search