Biomedical Engineering Reference

In-Depth Information

Effect of Hydrothermal Crystallization on the Bonding Strength of HACs

failure by chipping, spalling, delamina-

tion, and dissolution is being observed on explanted endoprostheses usually close to the

implant/coating interface [47,196,198]. This can be attributed to the existence of a layer of

ACP formed during rapid quenching of molten or semimolten droplets of calcium phos-

phate with exceptionally high cooling rates at the coating/Ti interface. The ACP layer is

thought to act as a fracture path [199] and owing to its comparatively high solubility will

be preferentially dissolved in vitro and in vivo [76,200,201], thus further weakening the

mechanical integrity of the interface [98,202]. Therefore, it is one of the challenges of coat-

In clinical application, a plasma-sprayed HACs failure by chipping, spalling, delamina-

Cs failure by chipping, spalling, delamina-

]. Therefore, it is one of the challenges of coat-

ing design to reduce the ACP content and improve the adhesion of the coating to substrate

by optimizing spraying parameters, modifying the precursor HA powder, or adding an

intermediate coating layer [40,203-208]. In addition, applying postheat treatments for pro-

98,202]. Therefore, it is one of the challenges of coat-

,202]. Therefore, it is one of the challenges of coat-

202]. Therefore, it is one of the challenges of coat-

for pro-

moting the crystallization of interfacial ACP is another effective method to improve the

interfacial adhesive bonding strength of plasma-sprayed HACs.

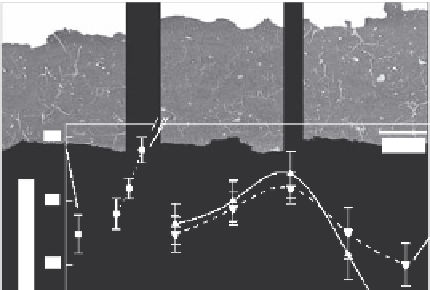

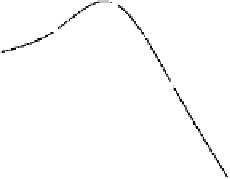

The bonding strength of the plasma-sprayed and different heat-treated HACs measured

by the tensile adhesion test according to ASTM C633 is shown in Figure 6.23. For both the

vacuum and atmospheric heat treatments, the bonding strength tends to increase with

increasing the heating temperature up to 600°C, whereas the bonding strength markedly

decreases with further increasing the heating temperature up to 800°C. For the hydrother-

mal treatment, the bonding strength is also significantly improved with the hydrothermal

crystallization of HA, and 150°C hydrothermally treated HACs has a higher bonding

strength (about 38.9 MPa for HT150) than both of the optimal conditions (at 600°C) for

atmospheric and vacuum heat-treated HACs (about 37.1 MPa for AH600, and about 36.0

MPa for VH600, respectively). Considering the cross-sectional features of the HACs also

shown in Figure 6.23, both the 600°C vacuum and atmospheric heat-treated specimens

203-208]. In addition, applying postheat treatments for pro-

-208]. In addition, applying postheat treatments for pro-

208]. In addition, applying postheat treatments for pro-

]. In addition, applying postheat treatments for pro-

s for pro-

40

4

4

4

4

4

4

40

50 µm

50 µm

50

50

50

50

50

5

5

5

5

5

5

5

5

5

5

5

0

µ

µ

µ

µ

µ

µ

µ

µ

µ

µ

µ

µ

µ

µ

µm

35

35

50 µm

30

30

As-sprayed HACs

Hydrothermal

Air heating

Vacuum heating

As-sprayed HACs

Hydrothermal

Air heating

Vacuum heating

25

25

20

20

01

00

400 500

400 500

600

7008

00

01

00

600

7008

00

Temperature (°C)

Temperature (°C)

TiO

2

FIGURE 6.23

Variation of bonding strength correlated with microstructural features after hydrothermal treatment and atmo-

spheric and vacuum heat treatments.

Search WWH ::

Custom Search