Biomedical Engineering Reference

In-Depth Information

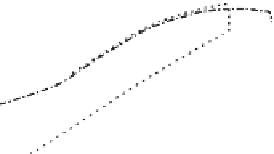

0.70

Holding stage

600ºC

Heating stage

0.35

0.00

Cooling stage

800ºC

400

º

C

500

º

C

600

º

C

700

º

C

800

º

C

-0.35

50 µm

-0.70

200

400

600

800

Temperature,

T

(

º

C)

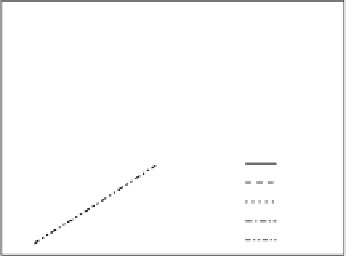

FIGURE 6.11

Dilatation curves of plasma-sprayed HACs obtained from heating, holding to cooling processes at 400°C to

800°C. (From Yang, C.W. and Lui, T.S.,

Mater. Trans

., 48(2), 211-218, 2007. With permission.)

an approximately linear thermal expansion when the heating temperature is in the range

from 100°C to 400°C. The CTE of an HAC within this temperature range is also evaluated

for about 15.6 × 10

−6

°C

−1

. In addition, it is worth noting that the nonlinear region of the

dilatation curves represents a consequence of greater crystallization of plasma-sprayed

HACs at 500°C to 800°C temperature interval. Table 6.1 lists the extent of dilatation val-

ues that are calculated from the dilatation curves cooling to about 100°C and significant

crystallization-induced contraction after heat treatments have been demonstrated. This

phenomenon can be recognized as a result of crystallization-induced contraction for these

coatings. The CTE data of crystallized HACs at these heating temperatures are calculated

from the slope of cooling stages, and the change in the CTE value also means that the effec-

s, and the change in the CTE value also means that the effec-

tive crystallization temperature of plasma-sprayed HACs by postheat treatments should

be higher than 600°C [64,120].

Compared with the as-sprayed HACs (Figure 6.6b), the cross-sectional images obtained

from 600°C and 800°C crystallized HACs represent significantly cracking features, as indi-

cated by the arrows in Figure 6.11. Figure 6.12 shows a typical SEM/SEI observation nearby

these contraction-induced cracks of the heat-treated HACs in the range of 600°C to 800°C,

and there is an obvious contrast within this area. Through the semiquantitative analysis of

SEM/EDS, the light gray contrast denoted by “C” with a Ca/P ratio of 1.61 represents the

occurrence of HA crystallization close to the contraction-induced cracks, and the dark gray

stages, and the change in the CTE value also means that the effec-

TABLE 6.1

Coefficient of Thermal Expansion (CTE, α) and Crystallization-Induced Contraction Ratio of

Heat-Treated HACs

HeatingTemperatures(°C)

α(×10

−6

°C

−1

)

a

ContractionRatio(%)

b

400

15.1

0.05

500

14.8

0.20

600

13.6

0.28

700

13.9

0.43

800

14.3

0.65

Source:

Yang et al.,

Mater. Trans

., 48(2), 211-218, 2007. With permission.

a

Values are measured from the slope of cooling curves to room temperature.

b

Data obtained from total dilatation of the sample dimension after cooling.

Search WWH ::

Custom Search