Biomedical Engineering Reference

In-Depth Information

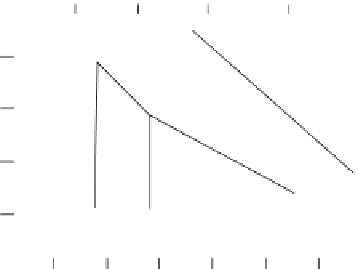

T

(

º

C)

1600

1500

1400

1300

3

Ap + CaO

2

Ap + C

4

P

α'C

3

P

C

4

P

C

4

P + Liq.

1

αC

3

P

C

4

P

T

2

T

1

0

5.25

5.50

5.75

6.00

6.25

6.50

10

4

/

T

(K)

FIGURE 6.3

Influence of ambient water vapor pressure on phase compositions of calcium phosphate. (From Gross et al.,

J.

Biomed. Mater. Res.

, 39, 580-587, 1998. With permission.)

(or 10

4

/T for Equation 6.4), this diagram shows the stable phases are α-TCP and TP when

the water vapor pressure is 1 mmHg (log

P

H

2

= 0). The stable phases are HA + TP, and

HA + CaO at partial water vapor pressures of about 10 mmHg (log

P

H O

2

= 1) and 100 mmHg

(log

P

H

2

= 2), respectively. It reveals that a higher partial water vapor pressure can help to

maintain and replenish the OH

−

groups within the HA crystal structure, and to increase

the phase-stabilized temperature of HA. Applying a steam atmosphere or a high steam

pressure is an effective method to maintain high thermal stability of HA during the manu-

facturing process [84]. For a calcium phosphate compound with a Ca/P ratio exceeding HA

by only a few percent, stable phases would be changed between α-TCP, TP, HA, and CaO.

When the partial water vapor pressure is presented, the formation of the α-CP, β-TCP, and

TP phases will be minimized and HA will be the more stable phase below 1550°C [8,12], as

shown in Figure 6.2b. But HA becomes unstable and it will still decompose into α-TCP and

TP following the reaction shown in Equation 6.3 at temperatures higher than 1550°C.

Plasma-Sprayed HACs

Thermal spray processing has been applied for many years to deposit layer coatings for

various purposes such as wear resistance, thermal barrier coatings (TBCs), biocompatibility,

and so forth. The major advantages of the thermal spray processes are the ability to apply

a wide variety of compositions, including most metallic and ceramic materials, without

significantly heating substrate surface to be coated [85]. The main thermal spray techniques

include flame spraying, atmospheric plasma spraying (APS), vacuum plasma spraying

(VPS), high velocity oxygen fuel (HVOF) spraying, arc metallization, and detonation

gun spraying. Among these techniques, the plasma spraying process is becoming the

extensively applied technique of the thermal spraying methods and is commonly used

to deposit HA into dental implants and orthopedic prostheses. Investigations into some

calcium phosphate compounds and HA coatings on metallic implants, such as Ti-6Al-4V,

Search WWH ::

Custom Search