Biomedical Engineering Reference

In-Depth Information

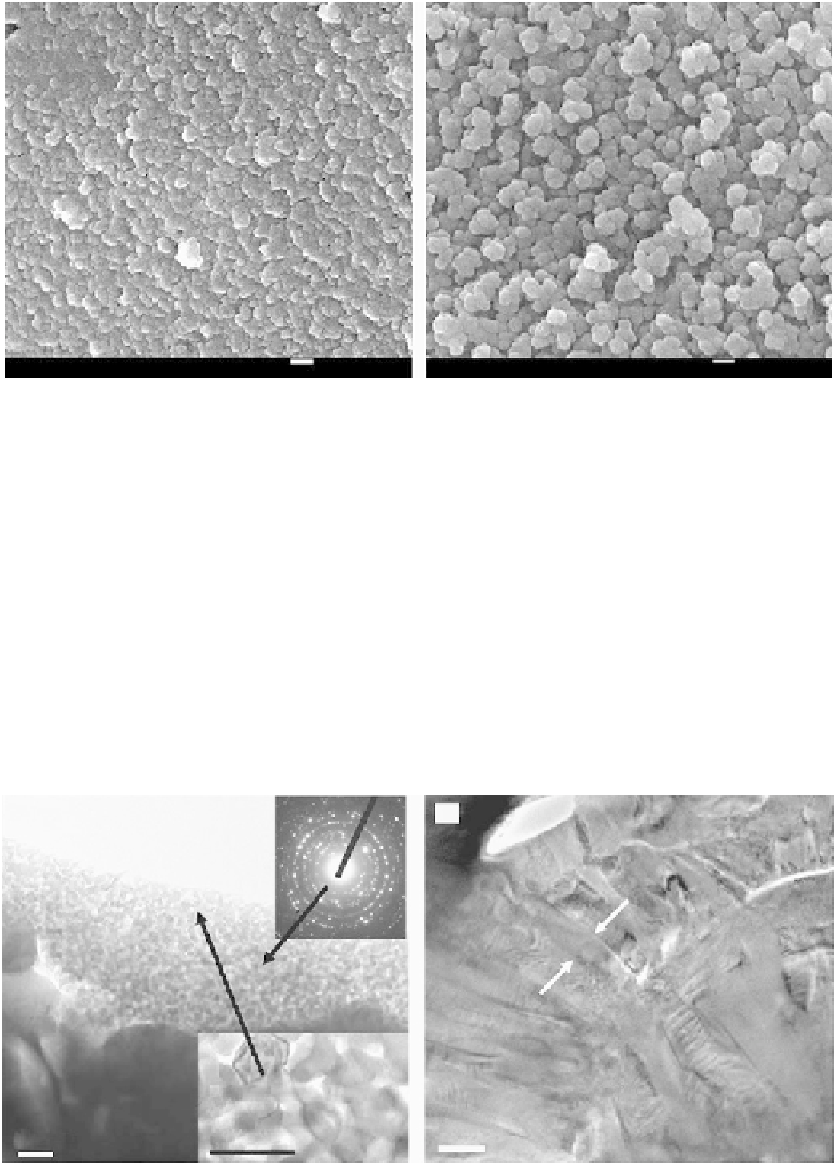

(a)

(b)

SEI 10.0 kV ×50,000 100 nmWD 8.2 mm

SEI

10.0 kV

×50,000

100 nm

WD 7.9 mm

FIGURE 5.22

SEM micrographs of nanosized titania coating on pure titanium prepared by plasma spraying. (a) Low magni-

fication, (b) high magnification. (From Liu et al.,

Biomaterials

, 26, 6143-6150, 2005. With permission.)

is composed of two layers. The outer layer is about 500 nm thick with grains size of less

than 50 nm, whereas the interior layer contains columnar grains with size ranging from

100 to 200 nm, as shown in Figure 5.23b. The SAD pattern discloses a crystalline structure

of the TiO

2

. XRD results further confirm that the coating mainly consists of rutile titania

with a small amount of anatase and TiO

2−

x

suboxide.

Fan et al. have also successfully prepared nanosized titania coatings using vacuum cold

spraying. This system is composed of a vacuum chamber and vacuum pump, an aerosol

room, an accelerating gas feeding unit, a particle-accelerating nozzle, a two-dimensional

work table, and the control unit. TiO

2

particles are accelerated by high-pressure He gas and

(a)

(b)

Outermost layer

Higher magnification

200 nm

100 nm

200 nm

FIGURE 5.23

TEM views of cross section of nanosized titania coating fabricated by plasma spraying and SAD pattern at

selected region. (From Liu et al.,

Biomaterials

, 26, 6143-6150, 2005. With permission.)

Search WWH ::

Custom Search