Biomedical Engineering Reference

In-Depth Information

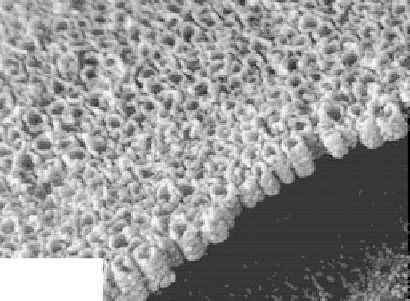

200 nm

FIGURE 5.2

SEM micrograph of first-generation nanotubes on surface and cross section. (From Gong et al.,

J. Mater. Res.,

16,

3331-3334, 2001. With permission.)

electrolyte. The typical surface and cross-sectional morphologies are depicted in Figure 5.2

(Gong et al. 2001). Recently, Allam and Grimes (2008a) reported successful fabrication of

titania nanotubes 2.5 μm long by using an Fe cathode. The second-generation fabrication

feature increased nanotube lengths to several micrometers and growth rates of around

0.25 μm/h. This is accomplished by adjusting the pH of both the aqueous KF and NaF elec-

trolytes to reduce the chemical dissolution rate of oxide (Michailowski et al. 2001). The rep-

resentative morphology of these second-generation titania nanotube arrays is displayed in

Figure 5.3. The third-generation synthesis employs organic electrolytes such as ethylene

L

= 1.5

µm

100 nm

100 nm

FIGURE 5.3

Lateral and cross-sectional views of second-generation titania nanotubes. (From Cai et al.

, J. Mater. Res.,

20,

230-236, 2005. With permission.)

Search WWH ::

Custom Search