Biomedical Engineering Reference

In-Depth Information

FabricationandCharacterizationofNanostructuredTitaniaCoatings

Fabrication of Titania Nanotube Arrays

A highly ordered and vertically oriented titania nanotubes array has been fabricated by

simple anodization of pure titanium and its alloys in various solutions. This nanoscaled

topography constitutes a materials architecture that offers a large surface area without

concomitant reduction in the geometric and structural order (Doohun et al. 2008; Grimes

and Mor 2009). The anodization process is economical, easy to operate, and capable of pro-

cessing targets with complex shapes. The geometry of the titania nanotube such as tube

length, tube diameter, tube spacing, wall thickness, and bonding strength can be precisely

designed and controlled by modifying the processing parameters. This nanoscaled archi-

tecture has aroused increasing attention in applications such as filtration, drug delivery,

and so forth.

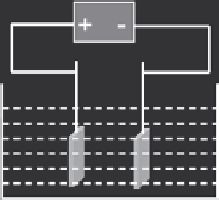

Equipment for Anodization

Anodization is an electrolytic process that generates a protective or decorative oxide film

on a metallic surface. Electrochemical anodization of titanium is usually carried out in an

aqueous electrolyte using a cell with the titanium sheet as the anode and a Pt or graphite

sheet as the cathode. Figure 5.1 illustrates a typical electrochemical anodization appara-

tus. The applied voltage forces the electron to the positive anode and surface metal atoms

are exposed to oxygen ions within the electrolyte. These metal atoms and oxygen react

and become an intrinsic part of the oxide layer. Initially, the increased voltage generates

no additional current flow until a threshold is reached where the electric field intensity

in the barrier is sufficient to force oxygen ions to diffuse across it and generate an ionic

current. The oxygen ions react with the metal and thicken the oxide layer. This process

goes on until the maximum applied voltage is reached, above which no desired reactions

become obvious. Two processing modes, namely constant current mode and constant volt-

age mode, are commonly used (Grimes and Mor 2009).

Background of Titania Nanotubes

From an historical perspective, fabrication of titania nanotubes has gone through four

generations. In 2001, Gong et al. fabricated the first generation of titania nanotube arrays

up to 500 nm in length by electrochemical oxidation of pure titanium in an aqueous HF

Power supply

Ti sheet

(anode)

Pt sheet

(cathode)

FIGURE 5.1

Scheme of typical electrochemical anodization cell for fabrication of titania nanotube arrays.

Search WWH ::

Custom Search