Biomedical Engineering Reference

In-Depth Information

Therefore for thermal-sprayed HA/ZrO

2

coatings, prevention, or alleviation of the chemi-

cal reaction is a challenge.

Co-/PostsprayTreatmentofHACoatings

Influence of HA Feedstock

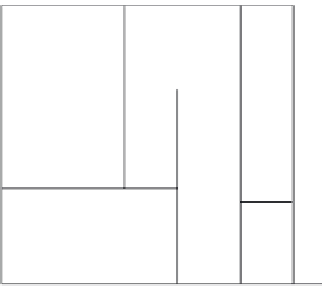

Thermal spray is basically a high-temperature processing approach. As discussed ear-

lier, HA can easily decomposite to other calcium phosphates at the temperatures beyond

~1000°C. Reciprocal transformation among these phases can prevail under certain condi-

tions. The equilibrium phase diagram for these transformations depending on tempera-

ture and content of P

2

O

5

is shown in Figure 4.31, which was usually utilized as a useful

tool in predicting the phases that could form upon solidification of sprayed HA powder.

The values of

T

1

(HA starts to fully transform to TCP and TTCP) and

T

2

(HA starts to trans-

form to TTCP) are dependent on the vapor pressure.

Generally, the temperature of plasma jet is approximately up to 20,000°C (Bertagnolli et

al. 1995), while the melting point of HA is around 1470°C and its transformation to other

phases usually takes place from around 1000°C. Therefore, at elevated temperatures dur-

ing plasma deposition, phase transformation from crystalline HA to other phases such as

TCP or CaO (Aoki 1994; Weng et al. 1994; Vu et al. 1997) seems inevitable. The following

decomposition reactions represent the usual chemical decomposition of crystalline HA

powders as they are heated and accelerated in the plasma jet or during splat formation:

Ca

10

(PO

4

)

6

(OH)

2

→ 2Ca

3

(PO

4

)

2

+ Ca

4

P

2

O

9

+ H

2

O↑

(4.13)

(Liu et al. 1994; Gross et al. 1998a; Ogiso et al. 1998b)

TCP +

TTCP

TCP

+

Liq.

T

1

CaO + TTCP

TTCP

HA

T

2

TCP

+

HA

TCP

+

DCP

CaO + HA

CaO

TTCP HA TCP P

2

O

3

% P

2

O

3

FIGURE 4.31

Schematic representation of CaO-P

2

O

5

-H

2

O system at fixed

P

H2O

. (From Harris, D.H., in

Thermal Spray Research

and Applications, Proceedings of the Third NTSC

, Long Beach, CA, May 1990, pp. 419-423. With permission.)

Search WWH ::

Custom Search