Biomedical Engineering Reference

In-Depth Information

1.6

1.18

1.2

1.15

1.06

0.8

0.4

HVOF1

HVOF2

HVOF3

Specimen designation

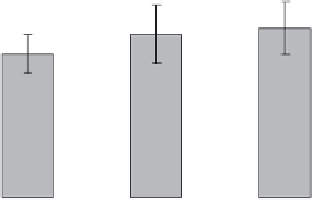

FIGURE 4.26

Critical strain energy release rate (

G

ss

) of the HA coatings obtained from 4-point bend test. (HVOF1, HA coating

made from 50 ± 10 μm powder; HVOF2, HA coating made from 40 ± 10 μm powder; HVOF3, HA coating made

from 30 ± 10 μm powder.) (From Li et al.,

Eng. Fract. Mech.

, 74, 1894-1903, 2007a. With permission.)

coatings are in the range of ~20 to 110 nm (Li et al. 2007a). These should act as the crack

path and accelerate the crack propagation as well during the bending. Typical failure mor-

phology reveals that there is no evidence of cracking parallel to the surface of lamellae.

The trace of the brittle fracture suggests that the existed defects at the splats' interface

might have been connected together as the propagation path of the crack. Furthermore,

the size and distribution of pores also play an important role in influencing both the crack

initiation and propagation processes (Ishihara et al. 2000); thus failure would occur when

sufficient micropores have been connected by an unbonded area between splats and trans-

lamella microcracks to separate that region from the remainder of the coating. The effect

of micropores located along the crack propagation path on the fracture toughness has been

discussed by Leguillon (1997). It was believed that the crack growth was made of succes-

sive sudden jumps at each void along the crack path. Thus, the existence of micropores

at the crack propagation path (splats' interface in this case) is detrimental to the fracture

property. Furthermore, it has been found that the thickness of the retained coating is very

much consistent with that of one splat or two. Nevertheless, the cohesion inside individual

splats is much better than that between individual HA splats, which also accounts for the

bending crack propagation along the splats' interface. Since the fracture occurred within

the coating, the existence of the hexagonal nanosized grains did not show obvious influ-

ence on the crack growth.

NanostructuredHA-BasedCompositeCoatings

HA materials are poor in the property, which can lead to the instability of surface crys-

tals in the presence of body fluids and local loading. In addition, HA cannot withstand

applied loading force (de Putter et al. 1987). Especially in a body environment, the

mechanical strength of HA is further reduced considerably by fatigue (Heimke et al. 1987).

Therefore, HA needs to be strengthened. A bond-coat made from bioinert ceramic and the

Search WWH ::

Custom Search