Biomedical Engineering Reference

In-Depth Information

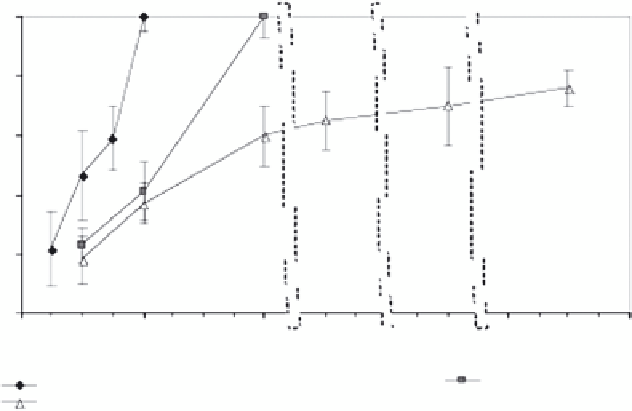

100

80

60

40

20

0

0

2

4 14 24 72

Incubation time (hrs)

HVOF-sprayed HA splats

(20-45 µm powders)

Plasma-sprayed HA splats (45-75 µm powders)

HVOF-sprayed HA splats (45-75 µm powders)

FIGURE 4.20

In vitro dissolution rates of the HA splats prepared by plasma and HVOF spraying. (Li et al.

Acta Mater.

, 52,

445-453, 2004c. With permission.)

of crystalline HA. According to the studies on phase transformations of HA at elevated

temperatures (Liao et al. 1999; Zhou et al. 1993), the dissolution results further confirmed

that HA decomposition mainly occurred within the melted part of the sprayed particles.

In other words, there could be a relationship between melt states of HA particles during

the spraying and phase composition of the resultant splat. A previous study (Khor et al.

2003b) and other ancillary results on dissolution behaviors of various CP phases (Cleries

et al. 1998) have pointed out that, compared to crystalline HA, TCP, and TTCP, ACP prefer-

ably dissolved within SBF. It has also been found that for a structure with a complex phase

composition, preferable dissolution still occurred, TCP preferably dissolved and it resulted

in remarkable voids within a CP coating (Cleries et al. 1998).

Apart from the capability of elucidating the phase information of individual splats, the

in vitro dissolution test can also give insight into formation mechanisms of the nanosized

pores in the nanostructured bioceramic coatings.

In order to enhance the properties of the HA-based bioceramic coatings, structure

improvement is the preferable approach. It is well known that the coatings actually

exhibit an accumulated layered structure, which is composed of individual splats. Besides

the contribution of the flaws (e.g., pores and cracks) and among splats, microstructure

of individual splats mainly accounts for the apparent structure of the bulk coating. The

microstructure characterization of a single splat is essentially fundamental for a good

understanding of thermal-sprayed coatings. Interesting results have been reported on

microstructure of thermal-sprayed splats (Pasandideh-Fard et al. 2002; Delplanque et

al. 1997; Jiang et al. 2001). In order to reveal detailed microstructure features in a single

splat, TEM must be adequately involved for the characterization. Using a special polish-

ing tool for their sample preparation, Chraska et al. reported the TEM observations on

cross sections of plasma-sprayed zirconia splats (Chraska et al. 2001; Chraska et al. 2002),

which revealed columnar grain growth within the splats. Among the structure variables,

which are responsible mainly for the mechanical properties, micropores play an impor-

tant role (Sevostianov et al. 2000; Leigh et al. 1997; Li et al. 1997). The micropores within

Search WWH ::

Custom Search