Biomedical Engineering Reference

In-Depth Information

16

16

14

14

12

12

wt.%

vol.%

10

10

8

8

C-1

C-2

C-3

C-4

C-5

Coating type

FIGURE 4.16

Content of α-TCP in as-sprayed crystalline coatings that shows the influence of spray parameters on phase com-

position of the resultant coatings. (From Khor et al.,

Biomaterials

, 25, 1177-1186, 2004. With permission.)

totally melted, the phases α-TCP, TTCP, and β-TCP are all exhibited in the resultant coating

(Wang et al. 1993a). The difference in the content of α-TCP in the coatings demonstrated

in Figure 4.16 further indicates that the extent of HA phase decomposition is significantly

related to the MFP during coating formation. From this point of view, the melt fraction

of powder is practically meaningful. It is clear that augmentation of starting particle size

results in decrease in melt fraction and hence contributes to decreased phase decomposi-

tion of HA.

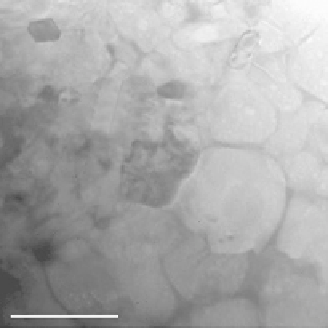

Interestingly, TEM observation evidenced that the melted part shows a smaller grain

size than the unmelted part (Figure 4.17) (Khor et al. 2004). It is noted that the HA grains

located in the unmelted part are of a far larger size than those in the melted part, which

underscores the influence of rapid cooling on grain growth during coating deposition. It

should be noted that grain size is mainly responsible for the mechanical performances

of materials. The relatively reduced grain size located in the resolidified zone, which is

Melted zone

Unmelted zone

1 µm

FIGURE 4.17

TEM image of as-sprayed HA coating showing different grain size and the interface between melted and

unmelted parts of HA splat. (From Khor et al.,

Biomaterials

, 25, 1177-1186, 2004. With permission.)

Search WWH ::

Custom Search