Biomedical Engineering Reference

In-Depth Information

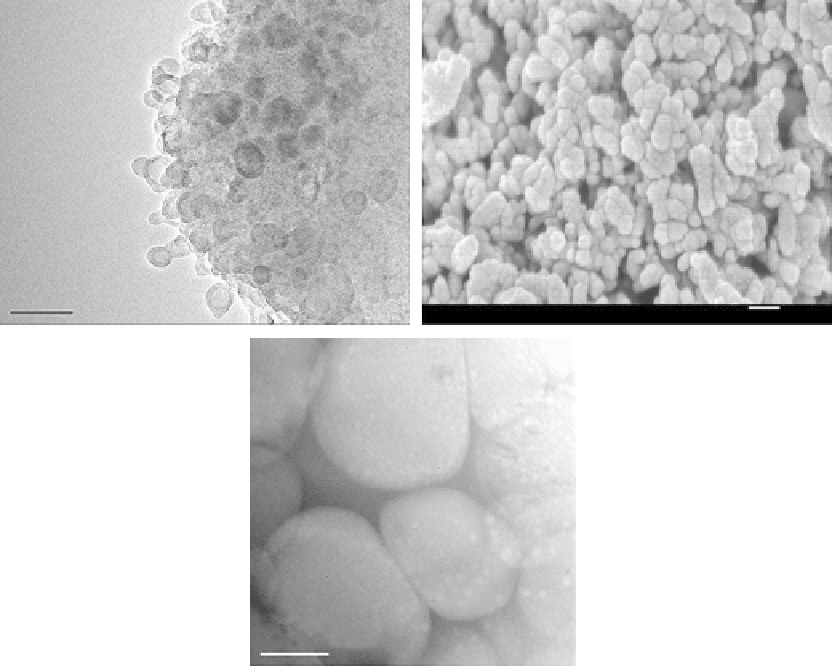

(a)

(b)

50 nm

SEI 5.0 kV ×90,000 100 nm WD 6 mm

(c)

200 nm

FIGURE 4.11

TEM and FESEM pictures of the HA splats. (a) TEM photo showing the predominant presence of the nanosized

grains (~30 nm) at fringes of the splat, (b) FESEM picture taken from the surface of the splat showing consistent

nanosized grains, (c) TEM photo showing the enlarged grains at the unmelted part within the HVOF splat.

(From Li, H., Khor, K.A.,

Surf. Coat. Technol.

, 201, 2147-2154, 2006.)

HA coatings can be achieved through the control of the melt state of HA particle in the

HVOF flame. It was evidenced that the molten part of the HA contributed to refined nano-

structures, while the unmelted part accounts for enlarged mcrosized grains (Li et al. 2006).

Investigation on melt-state of the particles is important toward understanding the micro-

structure of HA coatings. Since it is difficult to accurately determine the melt state of HA

from microstructure analysis of bulk coating, examination made on individual sprayed

HA particles and splats has been successful.

Thermal-sprayed coating is composed of liquid droplets that rapidly solidified upon

impact. It is likely that some droplets will contain entrapped gases attained during

their in-flight stage. Furthermore, it is well known that thermal sprayed coating shows

a layered structure, which is a splat-accumulated structure. Apart from the influence of

residual stresses, which is generated during coating formation, properties of the bulk coat-

ing are essentially derived from the characteristics of the solidified splats (Tadnno et al.

1997; Brown et al. 1994; Brown and Turner 1998). Therefore, the study on the properties of

sprayed particles and splats are essentially important.

Search WWH ::

Custom Search