Biomedical Engineering Reference

In-Depth Information

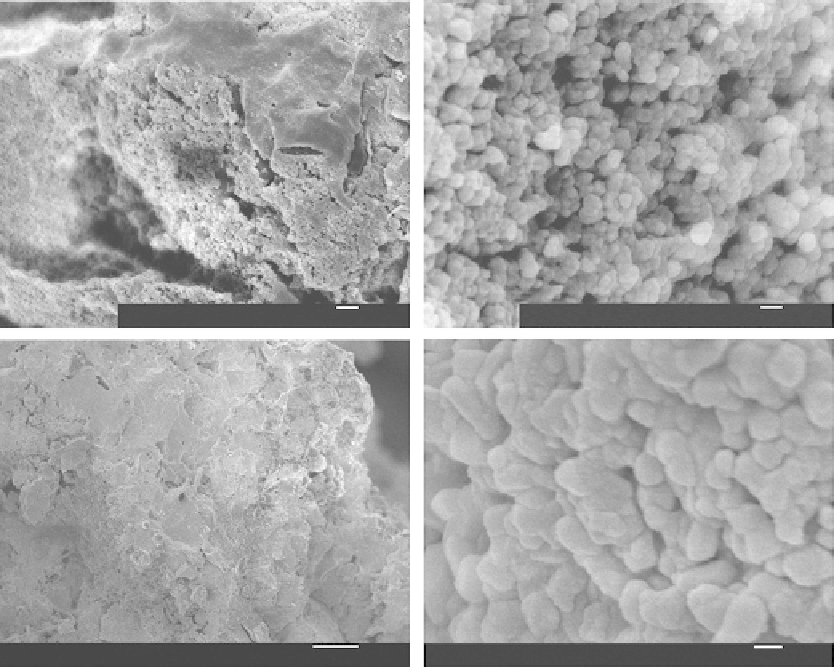

(a-1)

(a-2)

SEI 5.0 kV ×6000 1 µm WD 8 mm

SEI 5.0 kV ×60,000 100 nm WD 8 mm

(b-1)

(b-2)

SEI 5.0 kV ×1300 10 µm WD 8 mm

SEI 5.0 kV ×80,000 100 nm WD 8 mm

FIGURE 4.9

Typical field-emission SEM (FESEM) pictures of the HVOF coatings (made from 40 ± 10 μm powder) show-

ing nanostructures at (a) their surface and (b) fractured cross sections ((a-2) and (b-2) refer to closer observa-

tion on (a-1) and (b-1), respectively). (From Li, H., Khor, K.A.,

Surf. Coat. Technol.

, 201, 2147-2154, 2006. With

permission.)

et al. 2001). It should be noted that the extent of thermal decomposition of HA to trical-

cium phosphate (TCP), tetracalcium phosphate (TTCP), or amorphous calcium phosphate

(ACP) is closely related to the heat input, and hence the melt state of HA particles during

coating deposition (Gross et al. 1998b, 1998c; Ogiso et al. 1998a; Dyshlovenko et al. 2004;

Dyshlovenko et al. 2006).

The HVOF HA coatings show clearly the evidence of the presence of nanostructures at

both their surface and cross sections (Figure 4.9) (Li et al. 2006). Similar grain sizes can

be seen at both the coating surface and cross sections. In addition, the plasma sprayed

HA coatings also show predominate presence of the nanostructures. However, the sizes

of the grains (40-90 nm) are slightly smaller than those of the grains in the HVOF coat-

ings (50-110 nm). FESEM observation from the bottom side of the coating (the area with

intimate contact with the substrate) showed interesting microstructures (Figure 4.10) (Li et

al. SCT 2006). That is, the HVOF sprayed coatings made from the smallest powder (30 ± 10

μm) exhibit typical individual grains with hexagonal prismatic morphology (Figure 4.10a).

Most of the grains exhibit a size of <250 nm in height and <50 nm in side length (Figure

Search WWH ::

Custom Search