Biomedical Engineering Reference

In-Depth Information

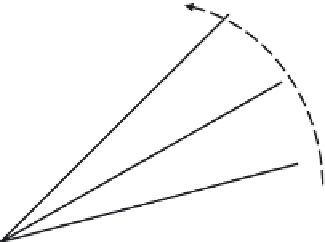

Increasing

voltage

Time

FIGURE 3.10

Effect of voltage on rate of deposition.

since the resistances are the same, then the current associated with the higher voltage must

be higher, and so the rate of deposition also must be higher.

Electrical Conductivity of Substrate

Most electrophoresis work is done using conducting substrates, including metals and

graphite. It is obvious that a highly conducting substrate is desirable in order to reduce

the resistance of the circuit. However, there have been a number of studies of deposi-

tion of ZrO

2

on porous insulating substrates backed by an electrically conducting surface.

These reports are summarized in Table 3.5 [90-95]. In these studies, it is considered that

the porosity is essential as it provides a pathway to complete the circuit to the conducting

back surface.

However, doubt has been cast on this requirement by recent work by the Australian

authors of the present work [35]. This work revealed that tin oxide (SnO

2

) could be depos-

ited on single-crystal sapphire (Al

2

O

3

) backed by graphite tape. The deposits were very

thin but they were coherent, flat, and of even thickness.

Surface Area of Substrate

When the current is reported, it usually is done in terms of the current density,

which is the current divided by the surface area of the substrate. It is clear that this will

have a significant impact on the rate of deposition because a higher current density depos-

its more quickly. That is, for the same voltage setting, a small substrate will be coated more

rapidly than a large one owing to the greater current.

Electrode Separation

The intensity of the electric field (V/cm) is a direct function of the electrode separation.

Since the voltage affects the rate of deposition, as shown in Figure 3.10, then a higher field

strength resulting from a smaller electrode separation increases the deposition rate.

Search WWH ::

Custom Search