Information Technology Reference

In-Depth Information

During the exercise the student (engine room operator) familiarises himself/herself

with the construction and operation of the fuel supply system, on his/her own starts

the emulsion creation subsystem and carries out a change analysis of basic energetic

and economic parameters for the engine with different percentage of water in the

FWE. The direct system service comes down to water supply into the emulsifier,

switching on the emulsifier and injecting the required water amount in the emulsion.

It needs to be remembered though that to obtain the same effective power after adding

water into the FWE it is necessary to increase the fuel pumps' capacity (fuel dose).

Thus, all parameters or setting restrictions must be corrected dependently on the fuel

dose [2].

The very first simulation status is the

ready for ship departure

status. The operator

starts the main engine and gradually increases its speed. For subsequent settings of the

engine speed and after stabilising the operational conditions, the engine room operator

registers selected parameters in the table (tab.2). It presents the engine and fuel

injection system parameters such as:

•

g

e

[g/kWh] - specific fuel consumption,

•

G

e

[kg/h] - mass fuel consumption per hour(FWE),

•

G

epal

[kg/h] - fuel capacity at the inlet of the emulsifier,

•

G

eH2O

[kg/h] - water capacity at the inlet of the emulsifier

•

n [rpm] - engine speed,

•

NO

X

[g/kWh] - NO

x

specific emission,

•

p

pal

[bar] - fuel pressure (FWE) at the inlet of the engine,

•

P

e

[kW] - engine effective power,

•

t

sr

[˚C] - average combustion temperature after the cylinders,

•

tpal [˚C] - fuel temperature (FWE) at the inlet of the engine,

•

W

o

[%] - fuel pump setting (load indicator) ,

•

Z [%] - smoke,

•

v [cSt] - kinematic viscosity at the inlet of the engine.

The number and type of parameters recorded during the exercise can be changed

depending on the educational needs.

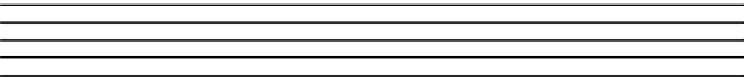

Table 2.

A template of the exercise measurement table (description in the text) [2]

…% m/m of water amount in the FEW…

n

g

e

G

e

epal

eH2O

p

pal

P

e

o

t

sr

t

pal

v

NO

X

Z

[rpm]

[g/kWh]

[kg/h]

[kg/h]

[kg/h]

[bar]

[kW]

[%]

[˚C]

[˚C]

[cSt]

[g/kWh]

[%]

30

40

50

60

70

The measured data should be collected at the start for pure fuel and for subsequent,

increasing amounts of water in the FWE up to the maximum amount of 30% m/m

H

2

O predictable for this system. Measures for 0%, 10%, 20%, 25% and 30% of water

Search WWH ::

Custom Search