Geology Reference

In-Depth Information

account that gold is also extracted as a byproduct in ores of other major metals

such as NiCu, CuMo or ZnPb.

The average ore grade of the gold deposits studied by Mudd (2007b) is 2.244

g/t. The average energy consumption of mines worldwide meanwhile is reported

at 143,000 GJ/t. The latter value includes all the processes of gold production:

mining, beneficiating, smelting, converting and refining. The authors are however

only interested in the first two steps. Kennecott Utah Copper (2006a) reports an

energy share for gold production of 27% for mining, 54% for concentrating, 12%

for smelting, 6% for refining and 1% for tailings. Hence, it is assumed that 81%

of the energy use in gold production is used for those steps directly relating to

mining and concentrating. Furthermore, the same company reports that 1 kg of

gold is obtained from 2,180 kg of blister copper, which in turn is produced from

concentrated copper after the beneficiating process at around 30% Cu-purity. In

the absence of other sources of information, it is assumed that after beneficiation,

gold has a concentration of x

r

= 1:38E 04.

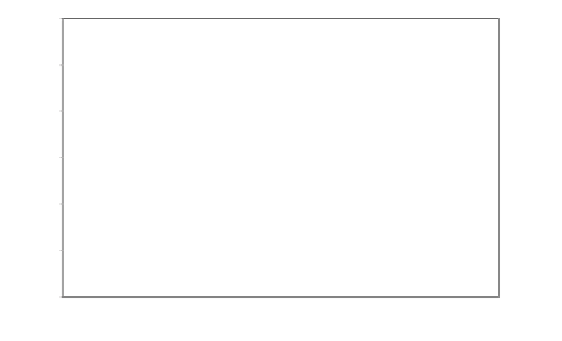

1200000

Real data set

Concentration Energy [GJ/t]

1000000

y = 135,664x

-0,285

800000

600000

400000

200000

0

0

10

20

30

40

50

60

70

80

90

Ore Grade [g/t]

Fig. 12.2 Energy requirements for gold production in function of ore grade. Adapted from Mudd

(2007b)

12.4.2 Copper

Data sets for energy requirements as a function of the copper ore grade are ob-

tained from the study of Mudd (2010a) of sulphidic ores which contain also cobalt

and nickel. Mudd allocates energy among minerals according to tonnage. It is

assumed that 60% of the whole energy recorded is used for the mining and con-

centration processes

1

. Kennecott Utah Copper (2004) reports an average grade for

Cu after beneficiation of x

r

=28%. For the smelting and refining stages, the authors

assume the value given by the ecoinvent database (Classen et al., 2007) (21.4 GJ/t).

1

See in Sec. 8.4 the data related to copper energy consumption from Chapman and Roberts

(1983) and Kennecott Utah Copper (2004).

Search WWH ::

Custom Search