Geology Reference

In-Depth Information

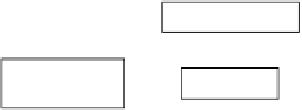

SORBENT

ADDITIONS STACK

Ti SWARF

OIL/WATER

TO SPECIALIST

RECOVERY

OPERATOR

SWARF

CRUSHING

CERAMIC

FILTER

CYCLONE

CENTRIFUGE

FINES TO

LANDFILL

FINES TO

LANDFILL

TITANIUM

SOLIDS

FERROUS

SCRAP

AFTERBURNER

THERMAL

DEGREASING

RAW MATERIALS WEIGHING

CYCLONE

FINES TO LANDFILL

MELTING

ELECTRIC INDUCTION FURNACE

(WATER COOLED)

STACK

BAG

FILTER

CASTING

FUME DUST

TO LANDFILL

FeTi INGOTS

INGOT TRANSFER TO FURTHER OPERATIONS

BREAKING, CRUSHING, GRINDING, SIEVING, PACKING

DESPATCH

Fig.8.11Ferro-titaniumproduction(IPPC,2009)

8.11.7 Niobium and Tantalum

At present, pyrochlores in carbonatite complexes are the mineral ores most exploited

for the obtaining of niobium. Open pit mines contain ores typically comprising 2.5-

3% Nb

2

O

5

which become physically concentrated to a 55-60% niobium oxide. This

oxide is mostly used for producing ferroniobium.

Furthermore, minerals containing tantalum often also have niobium which is

recovered as a co-product. The main mineral ores for tantalum and niobium are

Search WWH ::

Custom Search