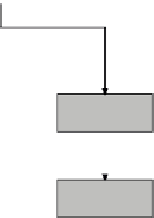

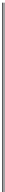

Geology Reference

In-Depth Information

Scrap

metallics, alloys

Sweeps

minerals

Photographic

materials

Melting

Incineration

Shredding

metallics

slag

Homogenisation

crushing, grinding,

blending

Analysis

Incineration

Washing

Analysis

Analysis

hydro-

metallurgy

pyro-

metallurgy

high Au

low Ag

high Ag

low Au

high Au

low Ag

high Ag

low Au

slag

matte (Cu

2

S)

flue dust

Smelting

(extraction)

chlorine

PbO or

Cu

2

O

bullion

Smelting

(Miller)

Cupellation

flue dust

Gold

Dore - Ag, Au, PM

nitric acid

nitric acid

Chemical

refining

Chemical

treatment

Electrolysis

Moebius or Balbach

Silver

PGM

solutions

Ag, Pd

solution

Au, PGM

slime

Au, PGM

slime

aqua regia

or HCl/Cl

2

Electrolysis

Wohlwill

or

Chemical refining

Silver chloride

separation

silver

refining

Gold

Pd solution

PGM

slime

Gold

PGM refining

PGMs

Fig.8.9Generalflowsheetforpreciousmetalrecovery(IPPC,2009)

8.9.1 Silver process

Perhaps surprisingly, silver ores are not the most important source of Ag. The

present economic limit of the exploitation of such ores must contain at least 0.01%

Ag (100 ppm) with the most important ones being argentiferous lead and lead-zinc

ores. Argentiferous copper ores can, additionally, contain variable amounts of Ni

and Co. Indeed most of the world's silver is taken from the byproduct of Pb=Zn (31-

50%), Cu,(25-30%), Ag (10-28%) and Au (10-14%) bearing deposits. After the ore

beneficiation, a typical feed for smelting may have a composition of Au (0.0007%),

Ag (0.034%), Pb (0.34%), Zn (4.43%) and Cu (28.3%) (Ecoinvent - Classen et al.

(2007)).

Search WWH ::

Custom Search