Geology Reference

In-Depth Information

stripping the remaining impurities by adding caustic soda and other reagents be-

fore cooling the lead so that the dross once again rises to the surface where it is

removed (IPPC, 2009; BCS, 2002b).

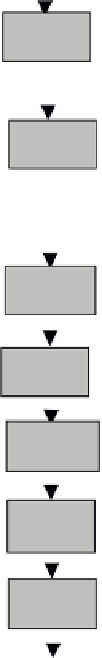

A general scheme of the production process of lead is shown in Fig. 8.7.

Fig. 8.7 Lead refining processes (IPPC, 2009)

8.8.2 Zinc process

Zinc is usually processed using the hydrometallurgical route of roasting, leaching

and electro-winning (Fig. 8.8). This process also allows for the recovery of valuable

elements such as Cd;Ge;Pb;Ag;In;Ga;Cu and sulphur. The roasting process of

zinc sulphide ore is undertaken in a fluidised bed roaster where the sulphides are

converted into SO

2

and metal oxides in an exothermal reaction. The heat is recov-

ered and the zinc oxide, referred to as calcine, is collected in cyclones and cooled.

Search WWH ::

Custom Search