Biomedical Engineering Reference

In-Depth Information

18.8.2. Stirrer Shaft

With stirred reactors, the

“opening” where stirrer shaft

enters the vessel is a potential

entry point for contamination.

The gap between the rotating

stirrer shaft and the fermentor

body must be sealed. If the

fermentor is operated for long

periods, wear at the seal opens

the way for air-borne contami-

nants. Several types of stirrer

seal have been developed to

prevent contamination. On

large fermentors, mechanical

seals are commonly used. One

part of the assembly is

stationary while the other rotates on the shaft; the precision-machined surfaces of the two

components are pressed together by springs or expanding bellows and cooled and lubricated

with water. Mechanical seals with running surfaces of silicon carbide paired with tungsten

carbide are often specified for fermentor application. Stirrer seals are especially critical if the

reactor is designed with a bottom-entering stirrer; double mechanical seals may be installed

to prevent fluid leakage. On smaller vessels, magnetic drives can be used to couple the stirrer

shaft with the motor; with these devices, the shaft does not pierce the fermentor body.

A magnet in a housing on the outside of the fermentor is driven by the stirrer motor; inside,

another magnet is attached to the end of the stirrer shaft and held in place by bearings. Suffi-

cient power can be transmitted using magnetic drives to agitate vessels up to at least 800 L in

size (Chisti Y. 1992 Assure Bioreactor Sterility. Chem. Eng. Prog. 88, 80

e

95). However, the suit-

ability of magnetic drives for viscous broths, especially when high oxygen transfer rates are

required, is limited.

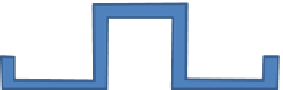

Spindle

Pinch bar

Flexible sleeve

FIGURE 18.12

A schematic of a pinch valve.

18.8.3. Fermentor Inoculation and Sampling

To prevent contamination during inocula transfer operations, both vessels are maintained

under positive air pressure. The simplest aseptic transfer method is to pressurize the inoc-

ulum vessel using sterile air; culture is then effectively blown into the larger fermentor

through a connecting pipe. The fermentor and its piping and the inoculum tank and its

piping including valves are sterilized separately before culture is added to the inoculum

tank. Because these connectors were open prior to being joined, they must be sterilized before

the inoculum tank is opened.

Sampling ports are commonly fitted to fermentors to allow for removal of broth intermit-

tently. The sampling ports must be constructed such that the outside (i.e. away from the

fermentor vessel) is sterilizable with steam before sample withdraw and can maintain high

temperature on the pipe to fend off foreign microorganisms to enter the fermentor vessel.

Search WWH ::

Custom Search