Biomedical Engineering Reference

In-Depth Information

and minimizing the number of openings

which improves the chances for maintain-

ing sterility. All surfaces within the vessel

must be smooth and are often electropol-

ished. O-rings are used for small openings,

typically for probes used in process

control. Gaskets are used for larger open-

ings such are piping connections to the

tank and the agitator mounting flanges.

Agitators are equipped with seals to

provide integrity between the vessel and

outside environment. Double mechanical

seals, with steamquench, are often utilized

on microbial and animal cell culture appli-

cations. Vessels are designed to be free

draining and cleanable. And ultimately,

bioreactor systems must be designed to

be steamable in place. Bioreactors are

designed to be steamable from the top,

down, so condensate cannot collect and

compromise the heat kill or organisms.

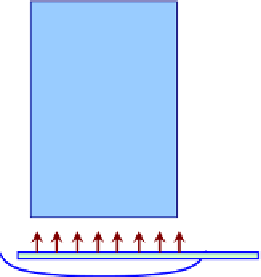

Fig. 18.4

illustrates a bubble column

reactor which provides a low shear envi-

ronment for the culture. These columns

are suitable for low viscosity Newtonian

broths. The structural packing (of high

porosity) can provide high contact area,

keeping bubbles small or breaking the

bubbles. They have higher energy efficien-

cies than agitated vessels in terms of the

amount of gas transfer per unit power.

However, bubble column reactors may be

limited by foaming and bubble coalescence

and are generally less flexible than stirred-

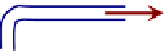

tank bioreactors. The multistage arrange-

ment (separated by structural packing)

alleviates the bubble coalescence problem,

further increasing mass transfer efficiency.

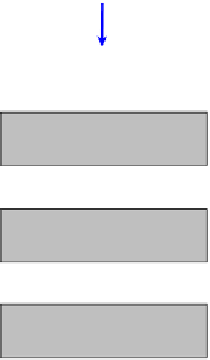

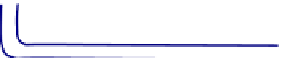

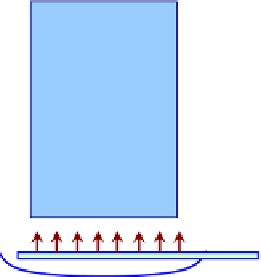

Fig. 18.5

shows a concentric draught-

tube bioreactor with annular liquid

down flow (loop reactor or airlift reactor).

Loop reactors have intermediate charac-

teristics between bubble columns and

stirred-tank bioreactors. The fast upflow-

ing air in the center draught tube carries

Liquid Feed

Exhaust gas

Structural packing

stages

Gas Supply

Valve

Product

FIGURE 18.4

Bubble column reactor.

Liquid Feed

Exhaust gas

Gas

Supply

Valve

Product

FIGURE 18.5

Internal airlift loop reactor.

Search WWH ::

Custom Search