Biomedical Engineering Reference

In-Depth Information

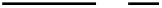

12.23. For the activated sludge unit shown in

Fig. P12.23

, the specific growth rate constants of

cells are given by

1h

1

,

K

S

¼

m

max

¼

0.01 g/L, YF

X/S

¼

0.50 g-X/g-S,

k

d

¼

0.05/h, and the

feed conditions are

Q

¼

500 L/h,

R

¼

0.4,

y

s

¼

0.1,

X

e

¼

0,

V

¼

1500 L, and

S

0

¼

1g/L.

(a) Calculate the substrate concentration (

S

) in the reactor at steady state.

(b) Calculate the cell concentration(s) in the reactor.

(c) Calculate

X

R

and

S

R

in the recycle stream.

12.24. Wastewater containing terephthalic acid (TA) is treated using two aerobic sludge tanks

in series. The first tank was 12 L in size and the second was 24 L. It is determined to

reduce the TA concentration from 5 g-COD/L to below 0.1 g-COD/L. The Monod

growth parameters are given by

m

max

¼

1.61/day and

K

S

¼

0.25 g/L. The results of the

experiments were reported in the following manner:

DðS

0

SÞ

¼

0:16

X

Tank

1

:

þ 0:62

S

DðS

0

SÞ

¼

0:3

X

S

þ 5:4

Design a CSTR sludge system to handle a wastewater flow of 1000 m

3

/day with

a loading of 5.6 kg-COD/m

3

.

12.25. An industrial waste with an inlet BOD

5

of 0.8 g/L must be treated to reduce the exit

BOD

5

level to no greater than 0.02 g/L. The inlet flow rate is 400 m

3

/h. Kinetic

parameters have been estimated for waste as

Tank

2

:

0.20 h

1

;

K

S

¼

m

max

¼

0.05 g-BOD

5

/L,

0.005 h

1

. A waste treatment unit of 3200 m

3

is

available. Assume a recycle ratio of 0.40 and

X

e

¼

YF

X/S

¼

0.50 g-CS600/g-BOD

5

,

k

d

¼

0. If you operate the concentrator at

2, find

S

and determine if sufficient BOD

5

removal is attained in a well-mixed

activated sludge process to meet specifications. What will be

X

(or CS600) and the

sludge production rate from this process?

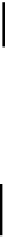

12.26. Consider a well-mixed waste treatment system (

Fig. P12.26

). The system is operated

with a reactor of 1000 L and flow rate of 100 L/h. The separator concentrates biomass

by a factor of 2. The recycle ratio is 0.7. The kinetic parameters are

c

R

¼

0.5 h

1

;

m

max

¼

K

S

¼

0.2 g/L, YF

X/S

¼

0.50 g-X/g-S,

k

d

¼

0.05/h. What is the exit substrate

concentration for

S

0

¼

1 g/L?

Q

,

S

0

(1 -

y

s

)

Q

X

,

S

Waste water

Effluent

S

e

,

X

e

(1 +

R

)

Q

V, X, S

Air

RQ

S

R

,

Settling

Tan k

X

R

Activated sludge reactor

(

R + y

s

)

Q

S

R

=

S

X

R

y

s

Q, S

R

,

X

R

Excess sludge

FIGURE P12.23

A schematic of an activated sludge unit.

Search WWH ::

Custom Search