Biomedical Engineering Reference

In-Depth Information

Q

,

S

0

(1 -

y

s

)

Q

S

e

,

X

e

X

,

S

Waste water

Effluent

(1 +

R

)

Q

V, X, S

Settling tank

or Separator

Air

RQ

S

R

,

X

R

Q

S

R

=

c

Rs

S

X

R

=

c

R

X

(

R + y

s

)

Activated sludge reactor

or Oxidation ponds

y

s

Q, S

R

,

X

R

Excess sludge

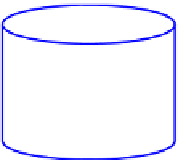

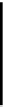

FIGURE 12.12

Schematic diagram of a typical wastewater processing unit.

approaches PFR behavior: circular tanks approach CSTR. The concentrated cells from the

settling tank are recycled back to the stirred-tank reactor. Usually, a mixed culture of organ-

isms is utilized in the bioreactor. Some of these organisms may produce polymeric materials

(polysaccharides), which help the organisms to agglomerate. Floc formation is a common

phenomenon encountered in activated sludge processes, which may impose some mass

transfer limitations on the biological oxidation of soluble organics; but good floc formation

is essential for good performance of the system, since large dense floes are required in the

sedimentation step. Cell recycle from the sedimentation unit improves the volumetric rate

of biological oxidation (i.e. high-density culture) and therefore reduces the residence time

or volume of the sludge reactor for a given feed rate. The recycle maintains the integrity of

biocatalysts (microbials) in the process in case of minor upsets or fluctuations. The recycle

ratio needs to be controlled to maximize BOD removal rate.

The selection of aerator and agitators is a critical factor in the design of activated sludge

processes. The aeration requirements vary depending on the strength of the wastewater

and cell concentration. Oxygen requirements for a typical activated sludge process are about

30

e

60 m

3

-O

2

/kg-BOD removed. Various aeration devices with and without mechanical

agitation can be used in activated sludge units. Mechanical surface aerators are widely

used for shallow activated sludge units. Surface aerators consist of partially submerged

impellers attached to motors mounted on fixed structures. Surface aerators spray liquid

and create rapid changes at the air

e

water interface to enhance oxygen transfer. Pure oxygen

may be used for high-strength wastewater treatment. Also, stagewise operation with pure

oxygen has been found to be a very effective method of wastewater treatment. The UNOX

Process, first developed by Union Carbide, is based on this concept. Other forms of aeration

include bubble aerators and fixed turbines.

The activated sludge system faces many uncontrolled disturbances in input parameters,

such as waste flow and composition. Such disturbances can lead to system failure (less

than adequate treatment of the waste stream). One type of disturbance is referred to as

shock

loading

. A shock load indicates the sudden input (pulse) of a high concentration of a toxic

compound. A CSTR design, of course, is less affected by such inputs than a PFR design.

One response to disturbances is sludge

bulking

.A

bulking sludge

has flocs that do not settle

well, and consequently cell mass is not recycled.

Bulking

sludge often results from a change in

Search WWH ::

Custom Search