Biomedical Engineering Reference

In-Depth Information

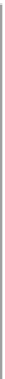

0.12

0.10

0.08

0.06

0.04

0.02

0.00

0.0

0.1

0.2

0.3

0.4

0.5

0.6

P

, g/l

FIGURE E12-3.3

Rate of production of secondary metabolite based on the batch fermentation data.

For the second reactor, there is high cell biomass already in the feed, and the key substrate

for cell growth is limiting. Therefore, growth in the second reactor is suppressed, while

secondary metabolite production is amplified. Therefore, we use

Eqn (E12-3.4)

and

Fig. E12-3.3

to find the concentration for the secondary metabolite coming out of the second

reactor.

Figure E12-3.3

shows that the line passing through (

P

¼

P

1

¼

0.079 g/L,

r

P

¼

0) with

slope of D

2

¼

0.505 g/L.

Figure E12-3.4

shows a schematic of the overall procedure we have used to determine

P

2

.

The production rate of the secondary metabolite is then

QP

2

¼

0.15/h intercepts secondary metabolite generation curve at

P

2

¼

51.6 g/h.

(b) Based on the discussions in part (a), a single chemostat would produce biomass rather

than secondary metabolite. Therefore,

Fig. E12-3.2

can be employed to determine the

biomass concentration, and then use

Fig. E12-3.1

to determine the secondary metabolite

concentration. D

0.075/h. We overlay the mass balance,

Eqn (E12-3.2)

on top of the rate curve obtained from

Fig. E12-3.1

. In the feed to the first reactor, the

medium is sterile (

X

0

¼

¼

120/1600/h

¼

0). There two intercepts and only one is used

X

¼

X

1

¼

7.29 g/L.

The corresponding

P

¼

0.115 g/L. The production rate of the secondary metabolite is then

QP

2

¼

13.8 g/h.

Therefore, two stages of chemostats increase the secondary metabolite concentration from

0.115 g/L to 0.505 g/L or the secondary metabolite production from 13.8 g/h to 51.6 g/h.

Example 12-4. In Example 12-3, the solution to the chemostat problem was solved by

differentiating the batch fermentation data. As one can observe from

Figs E12-3.2

and

E12-3.3

that the rate obtained contain higher error and it gives one less confidence on the

Search WWH ::

Custom Search