Biomedical Engineering Reference

In-Depth Information

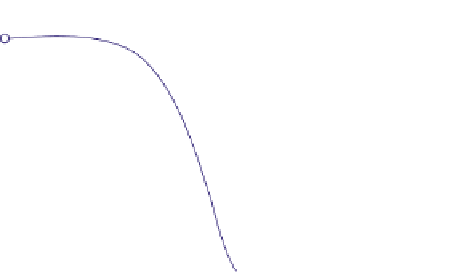

(a)

30

Glucose

Ethanol

Biomass

25

20

15

10

5

0

0

5

10

15

20

25

30

Batch cultivation time, h

(b)

20

15

Glucose

Ethanol

Biomass

10

5

0

0.0

0.1

0.2

0.3

0.4

0.5

, h

-1

D

FIGURE 12.8

Variations of total cell (viable and dead) dry biomass, glucose, and ethanol concentrations

during (a) batch and (b) continuous cultivations of

S. cerevisiae

LBG H 1022 (ATCC 3216) in a 4 m

3

air-lift

reactor with a glucose-limited medium. The data are from “Lotz M. 1986 Untersuchungen zur Hefekultivierung

auf Nebenprodkten der St

¨

rkegewinnung in einer Pilotanglage, PhD Dissertation, University of Hannover

and Lotz M., Fr

¨

hlich S., Matthes R., Sch

¨

gerl K. and Seekamp M. 1991 Bakers' yeast cultivation on by-products

and wastes of potato and wheat starch production on a laboratory and pilot plant scale.

Process Biochem

.

26: 301

e

311.”

productive variant will become dominant, decreasing productivity. In the batch culture, the

number of generations available is usually less than 25 (from slant cultures to a commercial-

scale fermentor) for the revertant cell to outgrow the more productive strain is limited. Cells

at the end of the batch are not reused (though resulting in higher cost). These considerations

of genetic stability are very important for cells with recombinant DNA and are discussed in

detail in Chapter 16.

Another consideration is operability and reliability. Batch cultures can suffer great vari-

ability from one run to another. Variations in product quality and concentration create prob-

lems in downstream processing and are undesirable. However,

long-term continuous

Search WWH ::

Custom Search