Biomedical Engineering Reference

In-Depth Information

(a)

Correlating the data with the logistic equation, determine the carrying capacity,

and carrying capacity coefficient.

(b)

Consider that glucose is the only substrate for the product (ethanol) generation

while some glucose also consumed for the cell growth. Correlate the ethanol

product rate with Monod model. Determine the specific maximum product

formation rate, saturation coefficient, and the yield factors YF

P/S

and YF

X/S

.

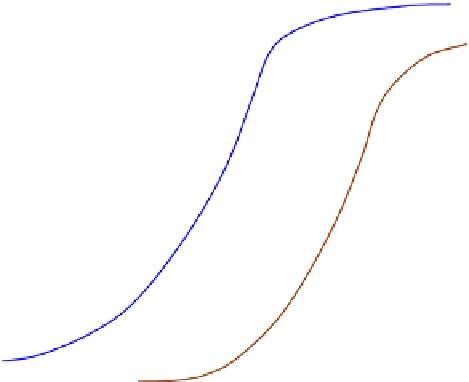

11.12.

Production of a secondary metabolite has been characterized using a small batch

reactor, and the kinetic data are shown in

Fig. P11.12

. You are to design a reactor to

produce 5 Mg/year of the product P. Batch production mode is chosen based on the

approved drug production method. Identical reaction conditions (same seed culture

concentrations, pH, and temperature) will be used as those for generating the data in

Fig. P11.12

. Experience is that for each batch of operations, there are 2 h additional time

needed for reactor loading, preparation, unloading after reaction, and reactor cleaning.

Determine the minimum reactor size required for this production.

FIGURE P11.12

8

1.6

7

1.4

6

1.2

1.0

5

0.8

4

X

P

3

0.6

0.4

2

0.2

1

0

0

0

2

4

6

8

10

12

14

16

18

t

, h

11.13.

The production of biomass is actually desired for the case of

Fig. P11.12

. Batch

production mode is chosen based on the approved drug production method. Identical

reaction conditions (same seed culture concentrations, pH, and temperature) will be

used as those for generating the data in

Fig. P11.12

. Experience is that for each batch of

operations, there are 2 h additional time needed for reactor loading, preparation,

unloading after reaction, and reactor cleaning. Determine the maximum production

rate for biomass.

Search WWH ::

Custom Search