Biomedical Engineering Reference

In-Depth Information

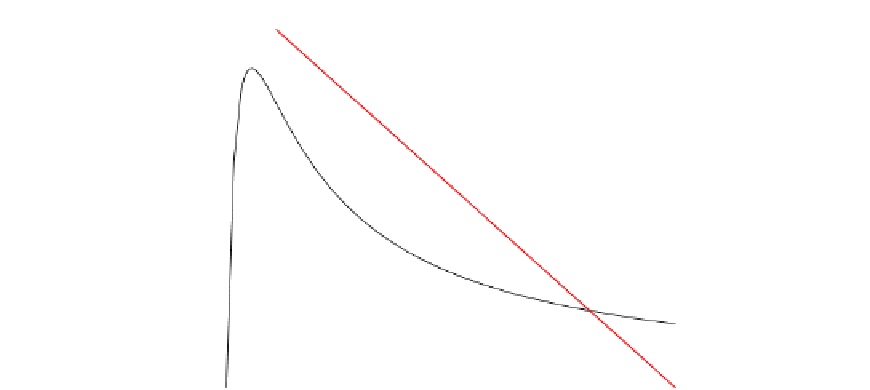

0.20

0.150

0.18

0.135

0.16

0.120

0.14

0.105

0.12

0.090

0.10

0.075

0.08

0.060

0.045

0.06

0.04

0.030

0.02

0.015

0.00

0

0

10

20

30

40

50

60

S

, mmol/L

FIGURE 8-4.4

generation rate

of product) three times. Therefore, there are three possible steady state solutions: S

The mole balance line intercepts with the consumption rate of substrate (

¼

¼

44, 6.5,

and 2.3 mmol/L. Correspondingly, the conversions are given by

S

0

S

S

S

f

S

¼

¼ 1

S

0

The three possible fractional conversions are: 0.267, 0.892, and 0.962.

0

(c) If the enzyme loading is reduced by 25%, i.e. [E]

0

¼

0.75[E]

0previous

. Based on Eqn

(E8-4.12)

,

the reaction rate is going to be reduced by 25%. Therefore, we can rescale the vertical axis

of

Fig. 8-4.1

(see the scale on the right on

Fig. 8-4.4

), while plotting the mole balance line,

Eqn

(8-4.13)

based on the new scale to find the possible steady-state solutions.

Now that only one steady-state solution is obtained. S

¼

48.5 mmol/L or the conversion

f

S

¼

0.192.

8.5. LARGE-SCALE PRODUCTION OF ENZYMES

Among various enzymes produced at large scale are proteases (subtilisin, rennet), hydro-

lases (pectinase, lipase, lactase), isomerases (glucose isomerase), and oxidases (glucose

oxidase). These enzymes are produced using overproducing strains of certain organisms.

Separation and purification of an enzyme from an organism require disruption of cells,

removal of cell debris and nucleic acids, precipitation of proteins, ultrafiltration of the desired

enzyme, chromatographic separations (optional), crystallization, and drying. The process

Search WWH ::

Custom Search