Biomedical Engineering Reference

In-Depth Information

5.11. GRAPHIC SOLUTIONS USING BATCH

CONCENTRATION DATA

We have learned so far how to perform reactor analysis for flow reactors based on known

reaction rate. The reaction rate is usually experimentally determined via examining the

concentration changes in a batch reactor, which will be discussed in Chapter 7. In this section,

we shall examine how to design or analyze a flow reactor based on the concentration profile

obtained in batch experiments at the same (feed) conditions.

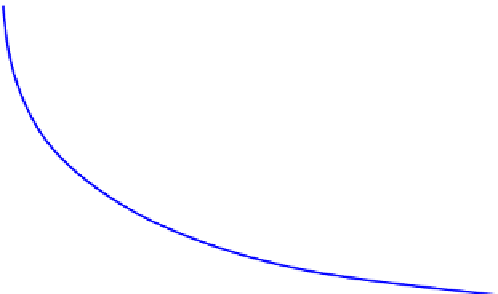

Figure 5.21

shows a typical (reactant) concentration profile obtained in a batch reactor.

Initially, the reactor is charged with the raw material with the key reactant concentration

of

C

A0

. As the reaction progresses, the concentration of A decreases with time until the reac-

tion is complete. If we look at a key product, the concentration would be increased with

increase duration of the reaction, just opposite to the reactant concentration. For ease of

discussion, we shall restrict ourself to constant density reactions, for example, condensed

phase (liquid and/or solid) reactions.

5.11.1. Solution of a PFR using Batch Concentration Data

For a reaction carried out in a steady PFR, we have learned that mole balance in a differ-

ential volume of the PFR leads to

d

F

j

d

V

r

j

¼

(5.11)

where

F

j

¼ QC

j

(5.105)

For constant density reactions, the volumetric flow rate

Q

is constant throughout the

reactor. Therefore,

Eqns (5.11) and (5.105)

lead to

d

C

j

r

j

d

V

Q

¼

(5.106)

C

A0

C

A

C

Ae

0

t

t

e

0

t

FIGURE 5.21

Variation of concentration with reaction time in a batch reactor.

Search WWH ::

Custom Search