Biomedical Engineering Reference

In-Depth Information

5.10. REACTIVE EXTRACTION

In renewable resources industries, woody biomass is commonly used as raw materials to

produce chemicals and materials. In this section, we devote some effort in learning how

a special type of continuous flow reactor with two contacting streams can be analyzed.

Woody biomass is solid and often reacts with a liquid stream to decompose woody

biomass to desired products. For example, hot water extraction of woody biomass employs

a water stream to extract hemicelluloses fromwoody biomass. Kraft pulping employs a white

liquor (aqueous sodium hydroxide and sodium sulfide solution) to degrade and extracting

lignin and other components from woody biomass. In both cases, the woody biomass

remains at the end of the reaction. Another example of such a reactive extraction process

is the ore leaching: a liquid stream is employed to extract desired element (or compound)

from “rocky” materials.

The reactive extraction process can be idealized as reaction occurring in two separate

streams with different flow rates (even opposing flowing directions). Without loss of gener-

ality,

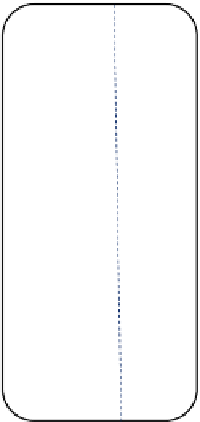

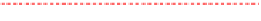

Fig. 5.20

shows a sketch of a conceptual reactive extraction tower. There are three

streams: a heavy reacting phase (for example woody biomass and its carrying liquid), a light

reacting phase (supplies active reacting agents to the heavy reacting phase), and a heat

exchange fluid phase. While the heat exchanging fluid phase is physically separated

T

H1

, Q

H1

, C

H1j

,

G

H1

T

L1

, Q

L1

, C

L1j

T

c1

, Q

c

Heat exchanging fluid

T

H

, G

H

, Q

H

, C

Hj

T

L

, Q

L

, C

Lj

T

c

, Q

c

.

V

V

J

j

Q

d

+

V

r

j

T

L

+ dT

L

,

Q

L

+ dQ

L

,

C

Lj

+ dC

Lj

T

c

+ dT

c

,

Q

c

T

H

+ dT

H

,

G

H

+ dG

H

,

Q

H

+ dQ

H

,

C

Hj

+ dC

Hj

T

c2

, Q

c

G

H2

,

T

H2

, Q

H2

, C

H2j

T

L2

, Q

L2

, C

L2j

FIGURE 5.20

A schematic diagram and idealization of reactive extraction tower.

Search WWH ::

Custom Search