Biomedical Engineering Reference

In-Depth Information

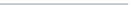

Nutrient Tanks

Penicillium

chrysogenum

Solvent

Spent solvent

Rotary filter

Seed

Fermenter

Fermenter

Ta n k s

Centrifugal

extractor

Surge Tank

Purification

column

Spent Mold

Centrifugal extractors

Evaporator

Spent solvent

Crystal wash

Slurry

Evaporator

Solvent

Procain, HCl

solution

Vacu u m

Solvent

Centrifuge

Freeze drier

Mixing

tan k

Mixing

tan k

Screen

Crystalline

potassium

penicillin

Procaine

penicillin

product

Filter

FIGURE 1.5

Schematic of penicillin production process.

We must continually reexamine the prejudices the field has inherited from the penicillin

experience.

It is you, the student, who will best be able to challenge these prejudices.

1.

8. BIOPROCESSES: REGULATORY CONSTRAIN

TS

To be an effective in bioprocess engineering, you must understand the regulatory climate

in which many bioprocess engineers work. The U.S. Food and Drug Administration (FDA)

and its equivalents in other countries must ensure the safety and efficacy of food and medi-

cines. For bioprocess engineers working in the pharmaceutical industry, the primary concern

is not reduction of manufacturing cost (although that is still a very desirable goal), but the

production of a product of consistently high-quality in amounts to satisfy the medical needs

of the population.

Search WWH ::

Custom Search