Biomedical Engineering Reference

In-Depth Information

k

1

s

C

A

0

ð1 þ k

1

s

Þð1 þ k

2

s

Þ

C

B

¼

(E5-8.14)

This maximum concentration of B (or the production rate of B) can be obtained by setting

s

m

¼

ð

1

þ

k

1

s

m

Þð

1

þ

k

2

s

m

Þ

s

m

½

k

1

ð

1

þ

k

2

s

m

Þþ

k

1

ð

1

þ

k

2

s

m

Þ

d

C

B

d

0 ¼

k

1

C

A

0

(E5-8.15)

2

2

s

ð1 þ k

1

s

m

Þ

ð1 þ k

2

s

m

Þ

which gives the contact time required for maximum production of B in a CSTR

1

k

2

k

1

s

m

¼

p

(E5-8.16)

and the corresponding concentration of B is given by

(E5-8.17)

s

!

2

k

2

k

1

C

B

max

¼ C

A

0

1 þ

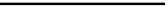

Figure E5-8.3

shows the ratio of the maximum concentration B in a PFR,

Eqn (E5-8.10)

to that

in a CSTR,

Eqn (E5-8.17)

, as a function of the kinetic rate constant

k

2

/

k

1

. One can observe that the

productivity to B is higher in a PFR than in a CSTR, as the ratio is always greater than unity.

Therefore, the optimum reactor type is PFR, with a contact time given by

Eqn (E5-8.9)

if the

desired product is the intermediate product B.

Example 5-8 shows that PFR is better suited for intermediate product production. This can be

easily interpreted from the concentration distributions. In a CSTR, the reactant concentration is

1.5

1.4

1.3

1.2

1.1

1.0

10

-4

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

10

4

k/k

2

1

FIGURE E5-8.3

The ratio of the maximum intermediate product B in a PFR to that in a CSTR as a function of the

kinetic rate constant ratio.

Search WWH ::

Custom Search