Biomedical Engineering Reference

In-Depth Information

-r

A

=

kC

A

(C

A0

-

C

A

)

1

-r

A

PFR

CSTR

0

C

Ae

C

A1

C

A0

0

C

A

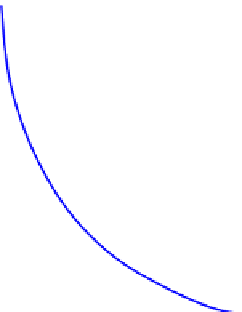

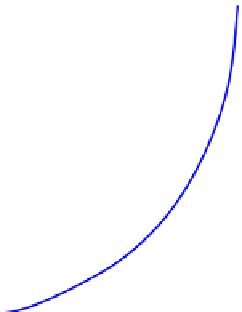

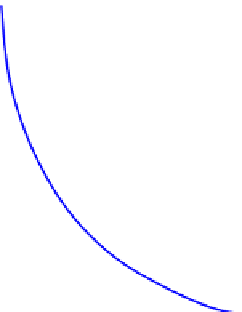

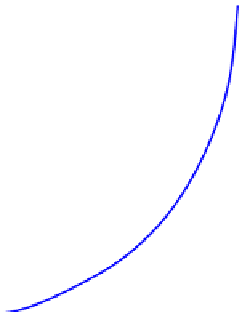

FIGURE E5-5.2

A sketch of the equal-volume CSTR and PFR reactor in series system for an autocatalytic

reaction.

r

A

)

1

vs

C

A

plot. This figure

helps us understand the volume of the CSTR is proportional to the rectangular area with the

top line corresponding to the reactor exit condition. Lower (

Figure E5-5.2

illustrates the solution of this example on the (

r

Ae

)

1

or higher reaction rate at

the reactor outlet reduces the reactor volume requirement. The volume of the PFR, on the

other hand, is proportional to the area under the rate curve.

5.6. RECYCLE REACTORS

Recycle reactors represent cases where part of the reactor effluent is returned to the reactor

inlet. In particular, this setup is useful for recycling the unreacted reactants, and/or catalysts.

To simplify the derivations, we introduced a new (fictitious) flow rate: flow rate of total

unreacted A (TUA). TUAmeans that all the products are reacted (reversely) back to reactant A.

Figure 5.15

shows illustrations of how CSTR and PFR can be setup in general. The feed is

consisted of A (

F

A0

) and some products (

F

TUA0

may not be equivalent to

F

A0

). The required

effluent from the reactor system consisted of

F

Ae

and overall conversion

f

Ae

. If we use conver-

sion to work through the problem, we have the fractional conversion at the inlet to the reactor

system:

F

TUA

0

F

A

0

F

TUA

0

f

A

0

¼

(5.69)

The fractional conversion of A leaving the reactor system is given by

F

TUAe

F

Ae

F

TUAe

f

Ae

¼

(5.70)

Let us assume that the ratio of flow that is recycled is

R

(recycle ratio) times the flow rate

leaving the reactor system. Since there are no other outlets leaving the reactor system, the

total molar flow rate at the only inlet (to the reactor system) and the outlet are identical.

Search WWH ::

Custom Search